Your cart is empty.

shop now

Your cart is empty.

shop now

Differential Scanning Calorimetry (DSC) is a thermal analysis technique that measures the heat flow between a sample and a reference material as they undergo controlled temperature changes. By quantifying the energy required to maintain temperature parity between the sample and reference, DSC reveals valuable insights into the sample's thermal properties.

The principle of DSC hinges on the fact that different materials possess varying heat capacities and undergo phase transitions at distinct temperatures. During these transitions, the sample absorbs or releases heat, leading to characteristic peaks on the DSC graph.

By integrating the area under the peaks on the DSC curve, we can quantify the enthalpy changes associated with phase transitions and reactions. This information provides a deeper understanding of the sample's thermal behavior.

A typical DSC instrument comprises a sample and reference pan, a temperature-controlled chamber, and a differential heat flow sensor. The instrument's design and capabilities play a crucial role in obtaining accurate and reliable results.

Careful sample preparation, including proper encapsulation and elimination of impurities, is essential to ensure representative measurements and avoid contamination-related issues.

Accurate temperature calibration is critical for reliable DSC measurements. Calibrating the instrument using standard reference materials helps establish the correct temperature scale.

The DSC graph displays endothermic peaks (heat absorption) and exothermic peaks (heat release), each corresponding to specific thermal events such as melting, crystallization, or reactions.

Interpreting the DSC graph allows us to identify different phase transitions and reactions, offering valuable information about the sample's thermal stability and behavior.

By analyzing the area under the peaks, researchers can quantify enthalpy changes, which are crucial for understanding the energy involved in various thermal processes.

Baseline drift in the DSC graph can obscure meaningful thermal events. Understanding the causes of baseline drift, such as instrument instability or temperature fluctuations, is vital for accurate data interpretation.

Contaminated or impure samples can yield misleading DSC results. Implementing proper sample handling techniques, using high-purity materials, and performing baseline measurements are essential for reliable analyses.

Limited sensitivity and resolution can hinder the detection of small thermal transitions. Researchers must optimize instrument settings and potentially employ techniques like Modulated DSC to enhance sensitivity.

Inappropriate heating or cooling rates can mask or exaggerate thermal events. Carefully selecting appropriate rates based on the sample's properties is essential for obtaining meaningful results.

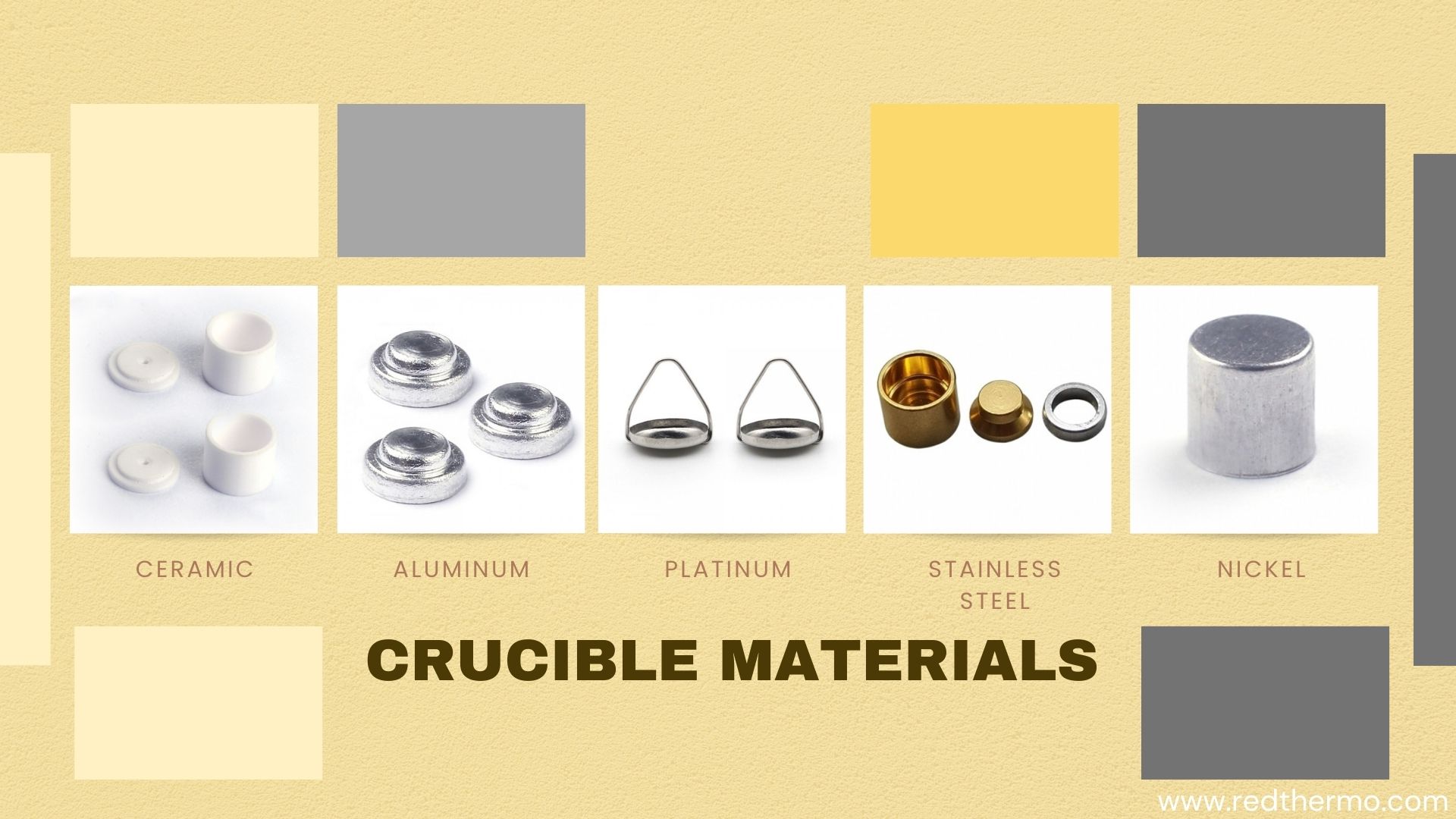

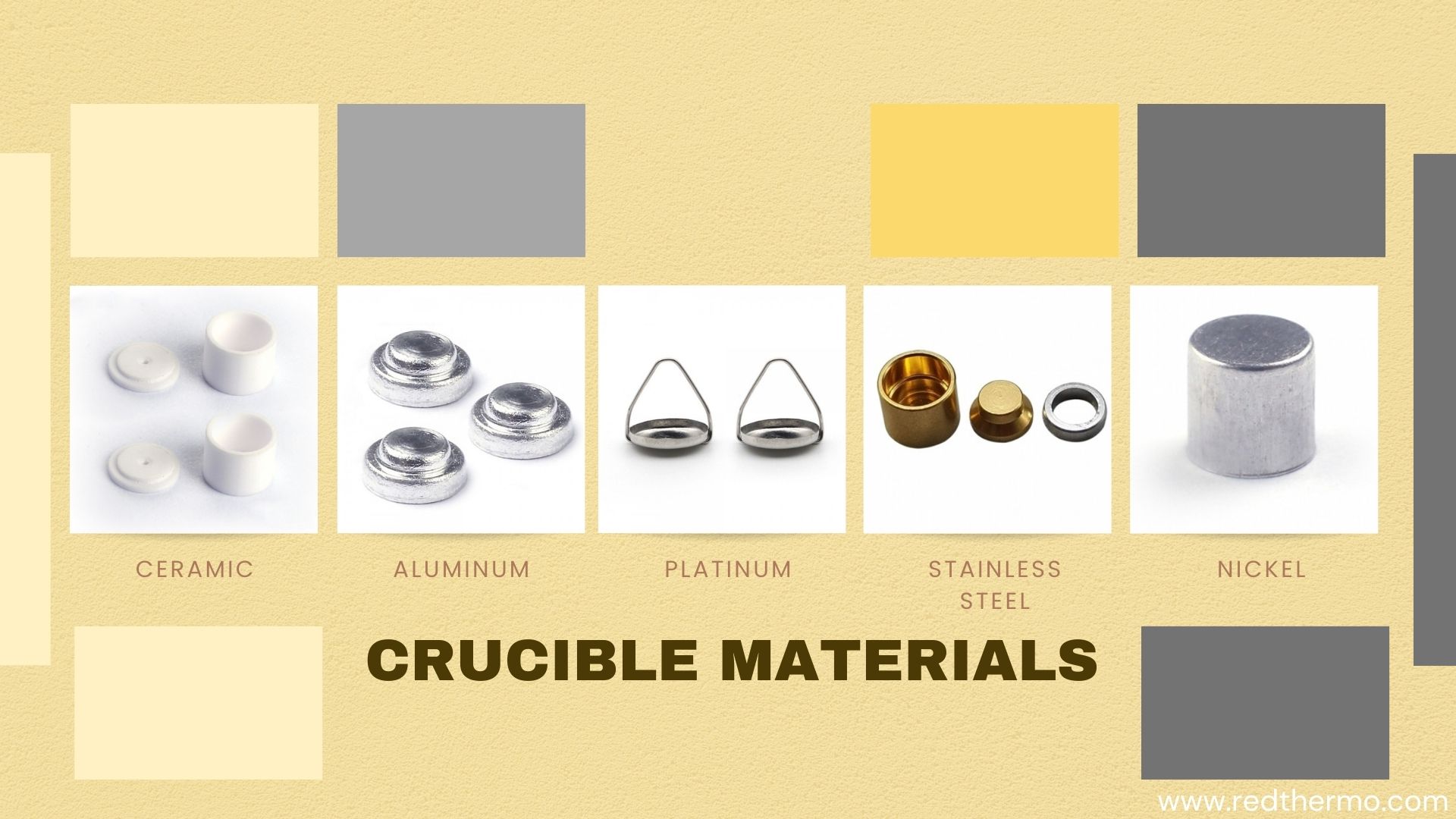

The choice of crucible material and design affects the DSC measurements. Compatibility with the sample and thermal properties should be considered to minimize interference with the thermal events.

Calibrating the instrument regularly, ensuring a stable environment, and verifying the reference material's purity can help address baseline drift issues.

Strictly adhering to sample handling protocols and employing suitable cleaning techniques can prevent sample contamination, ensuring accurate results.

Adjusting instrument settings, such as modulation parameters, and using higher sensitivity sensors can significantly improve sensitivity and resolution.

Understanding the sample's thermal behavior and adjusting the heating and cooling rates accordingly can reveal critical thermal events with enhanced clarity.

Selecting the appropriate crucible material and design based on the sample's properties can minimize interactions and interference, resulting in more accurate measurements.

Modulated DSC offers improved sensitivity and is particularly useful for analyzing complex samples with overlapping thermal events.

High-speed DSC enables the investigation of rapidly occurring reactions or phase transitions, providing valuable insights into dynamic processes.

Coupling DSC with Mass Spectrometry (MS) allows for the identification and analysis of evolved gases during thermal events, revealing information about sample composition and reactions.

DSC plays a vital role in pharmaceutical research by assessing drug stability, studying polymorphic forms, and examining drug-excipient interactions.

In the polymer industry, DSC aids in analyzing curing processes, determining glass transition temperatures, and evaluating thermal stability.

DSC is utilized in the food industry to assess product quality, study phase transitions in food components, and evaluate the effects of processing.

DSC is instrumental in characterizing nanomaterials and studying energy storage materials, enabling advancements in renewable energy technologies.

Advancements in DSC technology may lead to miniaturized and portable instruments, enabling on-site analyses and field applications.

Improved data analysis software and automated systems will simplify data interpretation and enhance experimental efficiency.

Integrating DSC with complementary techniques like TGA and TMA will provide a more comprehensive understanding of complex sample behaviors.

DSC is a vital tool for researchers and professionals seeking to understand the thermal behavior of materials. By interpreting DSC graphs, identifying phase transitions, and quantifying enthalpy changes, scientists gain valuable insights into sample characteristics. Troubleshooting common issues ensures reliable results, while advanced techniques offer deeper analysis for complex samples. The diverse applications of DSC in pharmaceuticals, polymers, food, and nanotechnology demonstrate its versatility. As technology progresses, future developments in DSC instruments promise greater portability, enhanced data analysis, and integration with complementary analytical methods, opening new horizons in thermal analysis and materials research.

A: DSC measures heat flow by recording the difference in energy required to maintain temperature parity between a sample and reference material during controlled temperature changes.

A: DSC graphs display endothermic peaks (heat absorption) and exothermic peaks (heat release) during phase transitions and reactions, providing insights into the sample's thermal behavior.

A: Enthalpy changes are quantified by integrating the area under the peaks on the DSC curve, which represents the energy involved in various thermal processes.

A: Common challenges include baseline drift, sample contamination, instrument sensitivity, heating/cooling rate optimization, and crucible selection. Proper calibration and handling can address these issues.

A: Techniques like Modulated DSC improve sensitivity for complex samples, while Evolved Gas Analysis coupled with DSC-MS identifies evolved gases during thermal events, providing additional sample information.

A: DSC finds application in pharmaceuticals for drug stability, polymers for curing processes, food industries for quality evaluation, and nanotechnology for characterizing nanomaterials and energy storage, among others.

A: Future developments may include miniaturization for on-site analyses, enhanced data analysis software, and integration with other analytical techniques, broadening DSC's capabilities in material characterization.