Your cart is empty.

shop now

Your cart is empty.

shop now

Content Table

1. Introduction - Explanation of DSC measurements - Importance of accuracy in DSC measurements | 6. Case studies and experimental evidence - Studies comparing aluminum pans with other materials - Analysis of lid effects on sample decomposition |

2. Functionality of aluminum sample pans and lids - Material properties of aluminum - Role of sample pans in DSC measurements - Significance of lids in maintaining sample integrity | 7. Recommendations for optimizing DSC measurements - Consideration of specific experimental requirements - Importance of pan and lid compatibility - Regular maintenance and quality control |

3. Impact of aluminum sample pans and lids on accuracy - Thermal conductivity of aluminum - Influence on baseline stability - Heat transfer effects | 8. Conclusion |

4. Challenges and limitations - Pan and lid selection - Sample contamination risks - Thermal effects on results | 9. FAQs |

5. Strategies to enhance accuracy - Use of reference materials - Proper pan and lid preparation - Calibration and validation procedures |

DSC measurements involve subjecting a sample to controlled heating or cooling while simultaneously measuring the heat flow to or from the sample. This technique allows researchers to observe and analyze changes in the sample's heat capacity as a function of temperature. Accurate DSC measurements are crucial for obtaining reliable data and meaningful results.

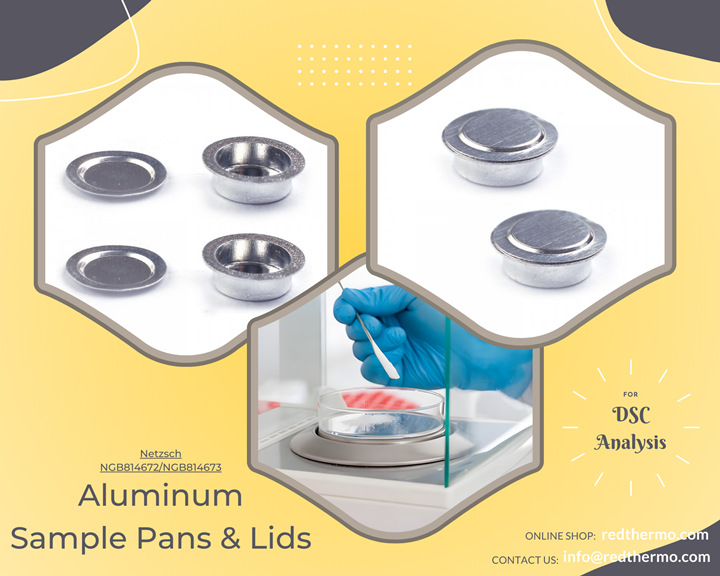

Aluminum is a widely used material for DSC sample pans and lids due to its excellent thermal conductivity, affordability, and ease of manufacturing. Aluminum pans hold the sample and ensure proper heat transfer during the DSC experiment. Conversely, lids play a vital role in maintaining sample integrity by preventing sample loss or contamination.

The thermal conductivity of aluminum plays a significant role in DSC measurements. Its high thermal conductivity allows for efficient heat transfer between the sample and the DSC instrument. This property is desirable as it ensures accurate temperature control and minimizes temperature gradients within the sample. However, the high thermal conductivity of aluminum can also cause challenges in achieving stable baselines, especially when using low thermal conductivity samples.

Another factor to consider is the heat transfer effects of aluminum sample pans and lids. The thermal conductivity of aluminum can lead to rapid heat transfer, potentially affecting the observed thermal transitions. This can result in distorted or shifted peaks, affecting the accuracy of the measurements.

When using aluminum sample pans and lids, certain challenges and limitations need to be considered. Pan and lid selection is crucial as different experimental requirements may call for specific designs or materials. The wrong choice of pan or lid can introduce artifacts or lead to inaccurate measurements.

Contamination risks are another concern. Aluminum sample pans and lids, if not properly cleaned and handled, may introduce impurities into the sample, affecting the results. Careful cleaning and preparation procedures should be followed to minimize contamination risks.

The thermal effects of aluminum on the results should also be taken into account. Some samples may undergo reactions or transformations due to the interaction with aluminum at elevated temperatures. This can lead to erroneous interpretations if not properly addressed.

To optimize the accuracy of DSC measurements using aluminum sample pans and lids, several strategies can be implemented. Firstly, the use of reference materials is highly recommended. Reference materials with known thermal properties can be measured alongside the sample to validate the DSC instrument's performance and calibrate the measurements.

Proper pan and lid preparation is essential to minimize contamination and ensure consistent results. Thorough cleaning of the pans and lids and their compatibility with the sample material should be considered. Preconditioning the pans and lids under the experimental conditions can also help stabilize the baseline and reduce artifacts.

Calibration and validation procedures should be performed regularly to verify the accuracy and precision of the DSC instrument. This includes checking the baseline stability, sensitivity, and temperature calibration. By following these procedures, the reliability of the DSC measurements can be significantly improved.

Several studies have compared aluminum pans with other materials to assess their impact on DSC measurements. These studies have shown that while aluminum pans provide efficient heat transfer, they may not be suitable for samples with low thermal conductivity. In such cases, alternative pan materials, such as platinum or ceramic, can be considered to minimize baseline disturbances.

Additionally, the effects of lids on sample decomposition have been investigated. It has been observed that tightly sealed lids can trap volatile components released during the sample decomposition, leading to measurement inaccuracies. To mitigate this, vented lids or controlled atmosphere conditions can be employed, allowing the volatile components to escape without compromising the measurement accuracy.

Several recommendations should be followed to optimize DSC measurements and ensure accurate results. Firstly, the specific experimental requirements should be carefully considered when selecting the appropriate sample pans and lids. Compatibility between the sample, pans, and lids is crucial for obtaining reliable data.

Regular maintenance and quality control of the DSC instrument is essential. This includes routine cleaning of the pans and lids and periodic calibration and validation procedures. The accuracy and precision of the measurements can be upheld by maintaining the instrument's performance.

Accurate DSC measurements are crucial for obtaining meaningful results in various scientific and industrial applications. Aluminum sample pans and lids, with their excellent thermal conductivity and functionality, play a significant role in DSC experiments. However, their impact on the accuracy of measurements should be carefully considered.

By understanding the thermal properties of aluminum, the challenges associated with its usage, and implementing appropriate strategies, researchers can optimize DSC measurements using aluminum sample pans and lids. Accurate and reliable DSC data can be obtained with careful pan and lid selection, proper preparation procedures, and regular calibration.

Q1: Can I use aluminum sample pans and lids for all types of samples in DSC measurements?

Yes, aluminum sample pans and lids can be used for a wide range of samples. However, alternative pan materials may be more suitable for samples with low thermal conductivity or in specific experimental conditions.

Q2: How can I minimize contamination risks when using aluminum sample pans and lids?

Thorough cleaning and proper handling of aluminum pans and lids are crucial to minimize contamination risks. Follow recommended cleaning procedures and ensure compatibility between the sample and the pans/lids.

Q3: Can the high thermal conductivity of aluminum affect the accuracy of DSC measurements?

The high thermal conductivity of aluminum can affect the stability of baselines, especially when using samples with low thermal conductivity. It is important to consider this when analyzing the results.

Q4: Are there any alternatives to aluminum sample pans and lids?

Yes, there are alternative materials available for sample pans and lids, such as quartz or ceramic. Depending on the specific experimental requirements and sample properties, these materials can be considered.

Q5: How often should I perform calibration and validation procedures for my DSC instrument?

Calibration and validation procedures should be performed regularly as part of routine maintenance. The frequency may vary depending on the instrument and the specific requirements, but performing these procedures at least once a year is generally recommended.