Your cart is empty.

shop now

Your cart is empty.

shop now

TGA is widely used in various fields, including material science, pharmaceuticals, and environmental analysis. It provides valuable information about a sample's thermal stability, decomposition kinetics, and composition. However, it is essential to optimize the experimental conditions of the TGA crucible to obtain accurate and reliable TGA results. The following sections provide a step-by-step guide on how to optimize the TGA crucible experimental conditions.

The TGA crucible material plays a critical role in the accuracy and reproducibility of TGA measurements. The commonly used TGA crucible materials are aluminum oxide, platinum, and quartz. Each material has its advantages and disadvantages, and the choice depends on the nature of the sample and the desired experimental conditions. For example, aluminum oxide crucibles are suitable for high-temperature applications, while quartz crucibles are ideal for analyzing volatile samples.

The TGA crucible should be clean and free from contaminants that may interfere with the TGA measurement. Heating the crucible at the same temperature range as the TGA experiment is recommended to eliminate any residual moisture or impurities. In addition, the TGA crucible should be cooled to room temperature before loading the sample to prevent thermal shock.

The sample should be weighed accurately and loaded into the TGA crucible using a spatula or tweezers. Ensuring that the sample is evenly distributed in the crucible is essential to avoid any bias in the TGA measurement. The amount of sample loaded should be optimized to obtain the desired measurement range and sensitivity.

The TGA experiment parameters, such as the heating rate, temperature range, and atmosphere, should be optimized based on the nature of the sample and the desired measurement accuracy. It is recommended to use a slow heating rate to obtain accurate results and to avoid exceeding the melting point of the TGA crucible material. Depending on the sample's sensitivity to oxidation or reduction, the TGA experiment can be conducted under different atmospheres, such as air, nitrogen, or inert gas.

The TGA experiment should be conducted under controlled conditions to obtain reliable and reproducible results. It is essential to monitor the TGA measurement continuously and record any anomalies or deviations from the expected behavior. The TGA measurement can be complemented with other techniques, such as Differential Scanning Calorimetry (DSC), to obtain more information about the sample's thermal properties.

The TGA data can be analyzed using various methods, such as calculating the derivative of the mass change curve, to obtain information about the sample composition, thermal stability, and decomposition kinetics. The TGA data can be further analyzed using thermokinetic models, such as the Kissinger-Akahira-Sunose (KAS) and Flynn-Wall-Ozawa (FWO) methods, to determine the activation energy and reaction mechanism of the sample.

Despite the careful optimization of the TGA crucible experimental conditions, certain issues may arise that affect the accuracy and reproducibility of the TGA measurement. These issues may include crucible contamination, sample decomposition, or improper heating rate. It is essential to troubleshoot these issues systematically and adjust the experimental conditions accordingly to obtain reliable results.

In conclusion, TGA is a powerful technique used to analyze a sample's thermal stability and composition. The TGA crucible experimental conditions play a crucial role in obtaining accurate and reliable TGA measurements. Optimizing the TGA crucible material, preparation, loading, and experimental conditions is critical to obtaining the best TGA results. Proper analysis and troubleshooting of the TGA data can provide valuable information about the sample's thermal properties and reaction kinetics.

1. What is TGA?

TGA stands for Thermogravimetric Analysis, a technique used to measure the change in mass of a sample as it is heated or cooled under controlled conditions.

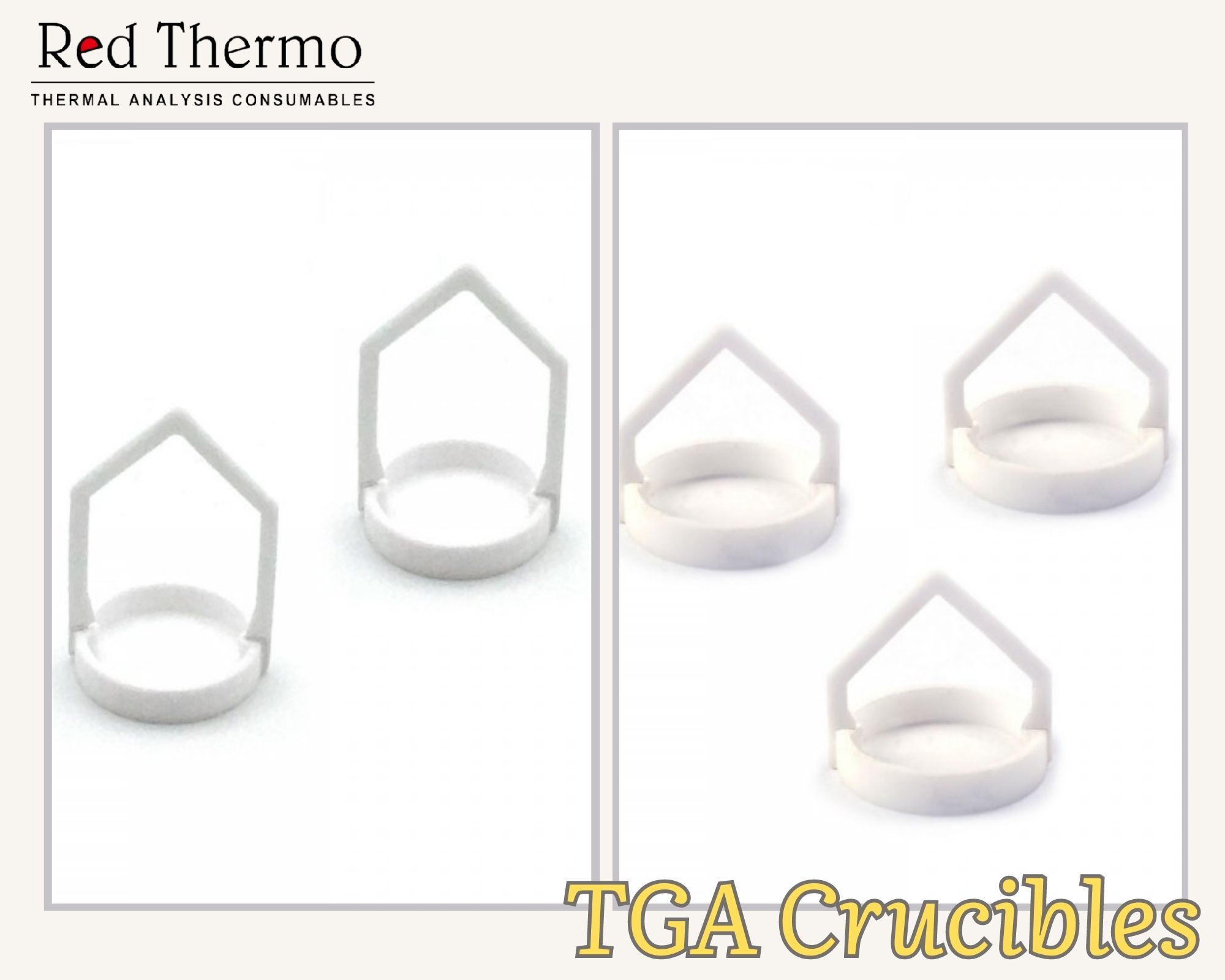

2. What is a TGA crucible?

A TGA crucible is a container used to hold the sample in a TGA experiment and measure its mass change as it is heated or cooled.

3. What are the commonly used TGA crucible materials?

The commonly used TGA crucible materials are aluminum oxide, platinum, and quartz.

4. How can I optimize the TGA experimental conditions?

The TGA experimental conditions can be optimized by choosing the right TGA crucible material, preparing the crucible, loading the sample accurately, and setting up the TGA experiment based on the nature of the sample and the desired measurement accuracy.

5. What should I do if I encounter issues with the TGA measurement?

If you encounter issues with the TGA measurement, you should troubleshoot the experimental conditions systematically and adjust them accordingly to obtain reliable results.