Your cart is empty.

shop now

Your cart is empty.

shop now

Thermogravimetric Analysis (TGA) is a powerful technique used to study the weight changes of a material as it is subjected to varying temperature and environmental conditions. TGA crucibles play a crucial role in this process, as they hold the sample during the experiment. Optimizing TGA crucible experimental conditions is essential to obtain accurate and meaningful results.

In this article, we will delve into the key factors that influence TGA crucible performance and how to optimize experimental conditions for the best outcomes.

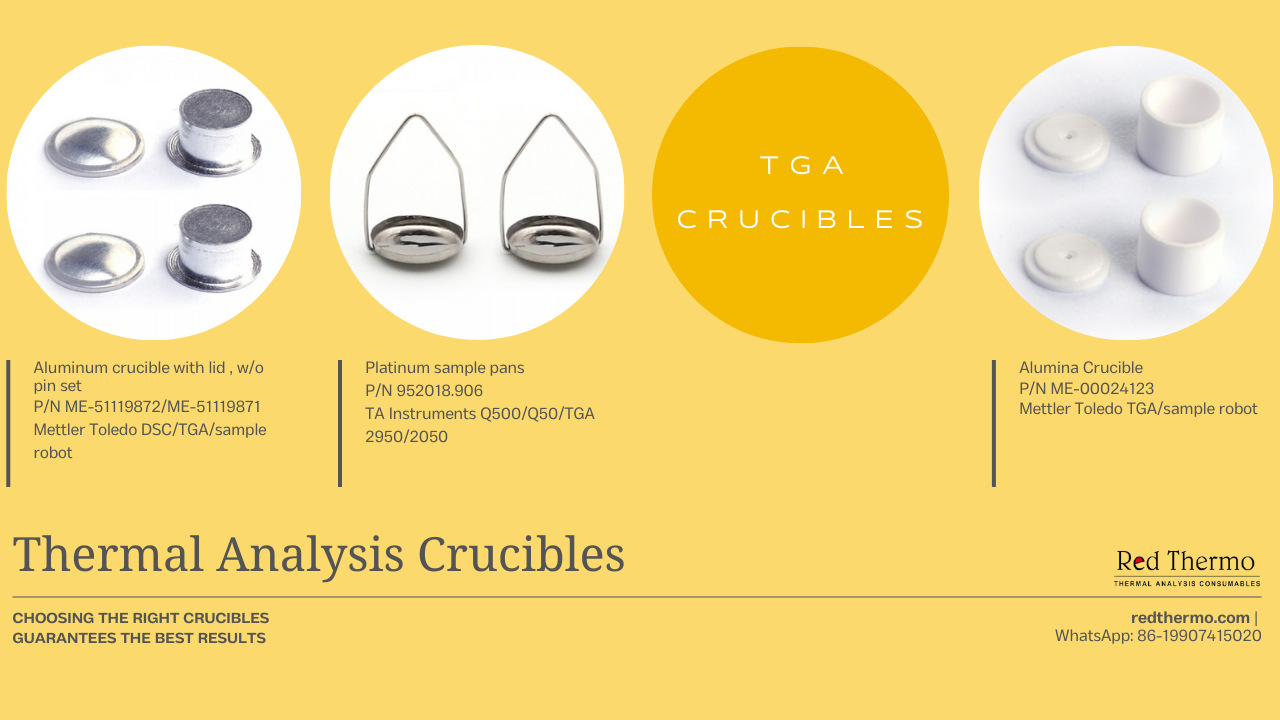

The choice of crucible material significantly impacts the TGA results. Crucibles are available in various materials such as alumina, platinum, aluminum, and more. Each material has different properties that can affect the thermal conductivity, reactivity, and compatibility with the sample. Select a crucible material that is chemically inert to the sample and can withstand the experimental temperature range.

The amount of sample used in the TGA crucible can affect the sensitivity and accuracy of the analysis. Too much sample might lead to overlapping weight loss events, while too little sample might result in undetectable changes. Ensure the sample size is appropriate for the crucible size and the experimental goal. Proper sample preparation, including grinding and homogenization, is crucial to ensure consistent results.

Before performing the actual experiment, it's essential to precondition the crucible. Heat the crucible to the desired temperature under the same experimental conditions to remove any residual impurities or moisture. This step ensures a clean baseline and prevents interference with the sample's weight loss events.

The heating rate determines how quickly the temperature increases during the TGA experiment. It's essential to choose an appropriate heating rate based on the nature of the sample and the phenomena you want to observe. A slow heating rate allows for better resolution of weight loss events, while a fast rate might mask certain thermal transitions.

The experimental atmosphere, whether it's air, inert gas, or specific gases, can significantly impact the TGA results. Some samples might undergo oxidation or reduction reactions that can alter their weight loss patterns. Choose an atmosphere that is compatible with the sample and the experimental objectives.

Calibrating the TGA instrument using standard reference materials is crucial for accurate measurements. Additionally, correct baseline subtraction is necessary to differentiate between the sample's weight loss events and the crucible's contribution. Failing to calibrate and correct the baseline can lead to erroneous results.

Thorough data analysis is the key to extracting meaningful insights from TGA experiments. Identify weight loss events, peaks, plateaus, and other patterns in the data. Correlate these findings with the sample's characteristics and behavior under different experimental conditions.

To ensure the reliability of your TGA results, it's important to replicate experiments under the same conditions. Reproducibility confirms the consistency of the data and validates the optimization process. If results from different experiments deviate significantly, it might indicate an issue with the experimental setup or conditions.

Choosing the appropriate temperature range is essential to capture all the relevant thermal events of the sample. Make sure the range covers all potential weight loss, decomposition, and phase transition events. This ensures a comprehensive analysis of the sample's behavior.

Maintain thorough documentation of all experimental conditions, observations, and results. This documentation is crucial for transparency, validation, and future reference. When reporting your findings, provide detailed information about the crucible type, sample size, heating rate, atmosphere, and any other relevant parameters.

Optimizing TGA crucible experimental conditions requires careful consideration of various factors, including crucible material, sample size, heating rate, atmosphere control, and data analysis. By selecting the right conditions and following best practices, researchers can ensure accurate and meaningful results from their TGA experiments. Remember that the goal is to uncover valuable insights into the thermal behavior of materials, and optimizing crucible conditions is a critical step in achieving that goal.