Your cart is empty.

shop now

Your cart is empty.

shop now

Contents:

1. Introduction - Importance of analyzing purity in inorganic compounds - Role of TGA crucibles in purity analysis | 7. Troubleshooting and Tips - Common issues during TGA analysis and their solutions - Tips for optimizing TGA crucible performance |

2. Understanding TGA Crucibles - Definition and purpose of TGA crucibles - Types of TGA crucibles available - Factors to consider when selecting a TGA crucible | 8. Advantages and Limitations of TGA Crucibles - Benefits of using TGA crucibles in purity analysis - Limitations and potential challenges to consider |

3. Preparing the TGA Crucible - Cleaning the crucible to remove impurities - Proper handling and storage of the crucible | 9. Case Study Examples - Real-world examples showcasing the use of TGA crucibles - Analyzing the purity of specific inorganic compounds |

4. Sample Preparation - Choosing the appropriate sample size and type - Proper weighing and loading of the sample into the crucible | 10. Conclusion |

5. Performing the TGA Analysis - Setting up the TGA instrument - Establishing the analysis parameters (temperature, heating rate, etc.) - Initiating the analysis and monitoring the results | 11. FAQs 1. What is the maximum temperature a TGA crucible can withstand? 2. Can TGA crucibles be reused after an analysis? 3. How long does a typical TGA analysis take? 4. Are TGA crucibles suitable for organic compound analysis? 5. What other techniques can complement TGA analysis for purity assessment? |

6. Analyzing the TGA Data - Interpreting weight loss or gain patterns - Identifying different phases and transitions - Assessing the purity of the inorganic compound |

Analyzing the purity of inorganic compounds is essential for quality control, research and development, and compliance with regulatory standards. Impurities can impact the compounds' performance, stability, and safety, making purity analysis a critical step in various industries such as pharmaceuticals, chemicals, and materials science.

TGA crucibles, specifically designed for thermogravimetric analysis, offer a reliable and accurate means of assessing the purity of inorganic compounds. TGA crucibles provide valuable information about thermal decomposition, phase transitions, and the presence of impurities by measuring the weight changes of a sample as it undergoes controlled heating.

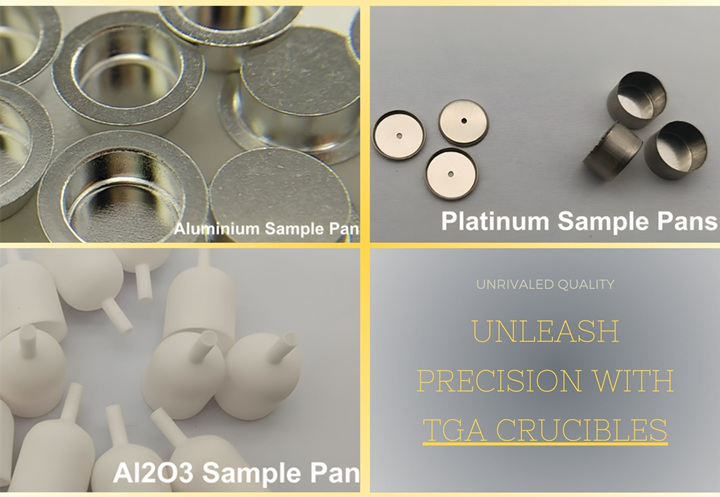

TGA crucibles are specialized containers that hold the sample during the thermogravimetric analysis. Depending on the specific analysis requirements, they are typically made of materials such as aluminum oxide, platinum, or aluminium. Different crucible types offer varying levels of chemical resistance, temperature stability, and compatibility with specific sample types.

When selecting a TGA crucible, factors such as the sample's melting point, reactivity, and desired analysis temperature range should be considered. Additionally, the crucible's capacity, shape, and compatibility with the TGA instrument's sample loading mechanism should be considered.

Before using a TGA crucible for purity analysis, it is crucial to ensure it is clean and free from any contaminants that could interfere with the analysis. Cleaning procedures may vary depending on the type of crucible material. Standard cleaning methods include washing with solvents, heating in a muffle furnace, or performing a self-cleaning cycle in the TGA instrument.

Proper handling and storage of the crucible are also essential. Crucibles should be handled with clean gloves or tweezers to prevent contamination from oils or residues on the skin. When not in use, crucibles should be stored in a clean and dry environment to avoid moisture absorption or exposure to reactive substances.

Accurate sample preparation is critical for obtaining reliable results in TGA analysis. The sample size and type should be chosen carefully based on the specific compound being analyzed and the sensitivity of the TGA instrument. Generally, a small and homogeneous sample is preferred to ensure uniform heating and accurate weight measurements.

The sample should be weighed precisely using a calibrated analytical balance. Care should be taken to minimize any external contamination during weighing. Depending on the sample's physical form, The weighed sample is loaded into the TGA crucible using clean tools such as a spatula or a pipette.

Setting up the TGA instrument correctly is essential for a successful analysis. The instrument should be calibrated regularly according to the manufacturer's guidelines to ensure accurate temperature and weight measurements. The analysis parameters should be selected based on the sample characteristics and analysis objectives, including the heating rate, temperature range, and atmosphere (such as air, nitrogen, or inert gas).

Once the instrument is set up, the analysis can be initiated. The TGA instrument will gradually heat the sample while continuously monitoring its weight. Over time, the weight loss or gain is recorded, and temperature data is collected simultaneously. The analysis should be conducted with proper precautions, including maintaining a controlled environment to minimize external influences.

Interpreting the TGA data involves analyzing weight loss or gain patterns and correlating them with the sample's thermal behavior. Significant weight loss can indicate the decomposition of the compound, while weight gain may suggest adsorption or reactions with the atmosphere.

Different phases and transitions, such as melting, sublimation, or chemical reactions, can be identified by analyzing the temperature and weight measurements. Comparing the obtained data with reference materials or known pure compounds can help assess the purity of the sample and detect impurities or additional components.

During TGA analysis, specific issues may arise. Common challenges include unexpected weight loss or gain, baseline drift, or abnormal temperature readings. If such issues occur, troubleshooting steps should be followed, including checking for instrument calibration, verifying sample preparation, and ensuring proper crucible handling and loading.

To optimize TGA crucible performance, several tips can be helpful. Using crucibles with appropriate dimensions for the sample size can improve heat transfer and prevent sample loss. Additionally, applying a thin layer of an inert material, such as alumina, on the crucible's bottom can enhance heat transfer and prevent sample reactions with the crucible material.

TGA crucibles offer several advantages for the purity analysis of inorganic compounds. They provide precise measurements of weight changes, allowing for detecting even small impurities or degradation products. TGA analysis is non-destructive, meaning the sample can be reused for further analysis or characterization. TGA crucibles are versatile, accommodating various sample types and compatibility with different analysis techniques, such as evolved gas analysis or coupled techniques like TGA-FTIR.

However, TGA crucibles also have limitations that should be considered. High-temperature applications may require specialized crucibles made of materials with superior heat resistance. Some crucible materials may react with specific sample components, leading to contamination or interference in the analysis. It is crucial to select the appropriate crucible material and consider its compatibility with the sample to obtain accurate and reliable results.

To illustrate the practical application of TGA crucibles in analyzing the purity of inorganic compounds, let's explore a couple of case studies:

In this case, a TGA crucible made of alumina was used to analyze the purity of calcium carbonate. In powder form, the sample was accurately weighed and loaded into the crucible. The TGA analysis revealed a gradual weight loss, corresponding to the thermal decomposition of calcium carbonate into calcium oxide and carbon dioxide. The absence of significant weight gain or additional phases indicated the high purity of the calcium carbonate sample.

TGA crucibles made of platinum were employed to assess the purity of lithium-ion battery electrolytes. The electrolyte samples were loaded into the crucibles, and TGA analysis was performed under controlled heating conditions. The weight loss observed during the analysis indicated the evaporation of volatile components in the electrolyte, such as solvents or impurities. The absence of weight gain or additional transitions confirmed the high purity of the electrolyte sample.

These case studies highlight the effectiveness of TGA crucibles in analyzing the purity of diverse inorganic compounds, ranging from simple compounds like calcium carbonate to complex electrolyte formulations.

Using TGA crucibles is a valuable approach for analyzing the purity of inorganic compounds. TGA crucibles provide insights into thermal behavior, decomposition, and impurity detection by accurately measuring weight changes during controlled heating. Proper sample preparation, instrument setup, and data analysis are crucial for reliable results.

TGA crucibles offer advantages such as high sensitivity, compatibility with various sample types, and non-destructive analysis. However, carefully considering crucible material selection, potential reactivity, and temperature limitations is necessary to ensure accurate and meaningful purity analysis.

In summary, TGA crucibles play a vital role in assessing the purity of inorganic compounds, enabling researchers and industries to maintain high-quality standards, identify impurities, and optimize material performance.

1. What is the maximum temperature a TGA crucible can withstand?

TGA crucibles are available in different materials, each with its own temperature limits. Common crucible materials like alumina or platinum can typically withstand temperatures ranging from a few hundred degrees Celsius to over 1000 degrees Celsius.

2. Can TGA crucibles be reused after an analysis?

Yes, TGA crucibles can often be reused after an analysis. Proper cleaning and handling procedures should be followed to ensure the removal of any residues or contaminants from previous analyses.

3. How long does a typical TGA analysis take?

The duration of a TGA analysis depends on various factors, including the sample type, heating rate, and the desired level of resolution. Generally, a TGA analysis can take a few minutes to several hours.

4. Are TGA crucibles suitable for organic compound analysis?

TGA crucibles are primarily designed for inorganic compound analysis. While they can be used for organic compounds, special considerations, such as potential reactivity or thermal degradation, should be considered. Alternative techniques like Differential Scanning Calorimetry (DSC) or Simultaneous Thermal Analysis (STA) may be more suitable for organic compound analysis.

5. What other techniques can complement TGA analysis for purity assessment?

Various techniques can complement TGA analysis to gain a comprehensive understanding of sample purity. Some complementary techniques include Fourier Transform Infrared Spectroscopy (FTIR), Mass Spectrometry (MS), X-ray Diffraction (XRD), and Gas Chromatography (GC). These techniques provide additional information about chemical composition, structural analysis, and impurity identification.