Your cart is empty.

shop now

Your cart is empty.

shop now

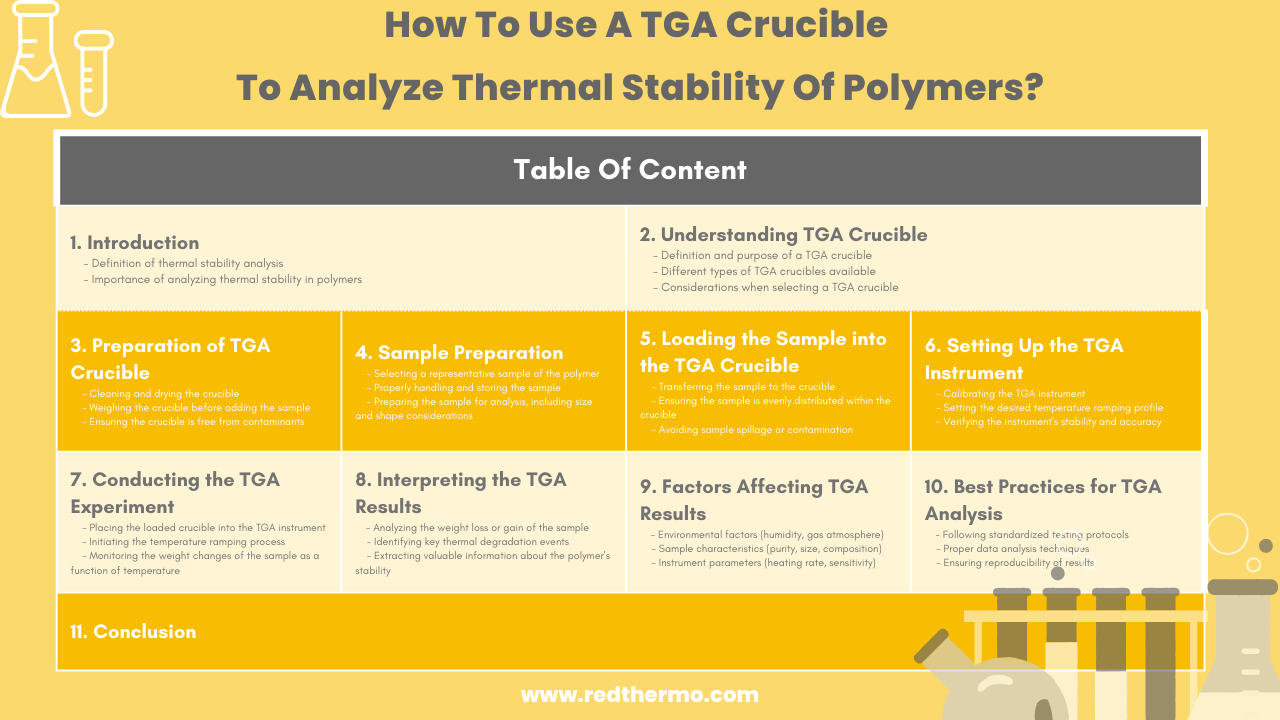

1. Introduction - Definition of thermal stability analysis - Importance of analyzing thermal stability in polymers | 2. Understanding TGA Crucible - Definition and purpose of a TGA crucible - Different types of TGA crucibles available - Considerations when selecting a TGA crucible |

3. Preparation of TGA Crucible - Cleaning and drying the crucible - Weighing the crucible before adding the sample - Ensuring the crucible is free from contaminants | 4. Sample Preparation - Selecting a representative sample of the polymer - Properly handling and storing the sample - Preparing the sample for analysis, including size and shape considerations |

5. Loading the Sample into the TGA Crucible - Transferring the sample to the crucible - Ensuring the sample is evenly distributed within the crucible - Avoiding sample spillage or contamination | 6. Setting Up the TGA Instrument - Calibrating the TGA instrument - Setting the desired temperature ramping profile - Verifying the instrument's stability and accuracy |

7. Conducting the TGA Experiment - Placing the loaded crucible into the TGA instrument - Initiating the temperature ramping process - Monitoring the weight changes of the sample as a function of temperature | 8. Interpreting the TGA Results - Analyzing the weight loss or gain of the sample - Identifying key thermal degradation events - Extracting valuable information about the polymer's stability |

9. Factors Affecting TGA Results - Environmental factors (humidity, gas atmosphere) - Sample characteristics (purity, size, composition) - Instrument parameters (heating rate, sensitivity) | 10. Best Practices for TGA Analysis - Following standardized testing protocols - Proper data analysis techniques - Ensuring reproducibility of results |

11. Conclusion | 12. FAQs |

Polymers are widely used in various industries, ranging from packaging materials to automotive components, due to their unique properties. However, the performance and durability of polymers can be significantly affected by temperature. Analyzing the thermal stability of polymers using techniques like TGA can provide valuable insights into their behaviour under different thermal conditions.

A TGA crucible is a small container made of a thermally stable material, such as aluminum, alumina or platinum, designed to hold the polymer sample during the TGA analysis. The crucible must be compatible with the temperature range of the experiment to prevent any unwanted reactions or degradation. Various types of crucibles are available, including open or closed designs, depending on the specific requirements of the analysis.

Before using the TGA crucible, it is crucial to ensure its cleanliness. Any contaminants present in the crucible can interfere with the analysis and lead to inaccurate results. Cleaning the crucible involves washing it with a suitable solvent and drying it thoroughly. After cleaning, the crucible should be weighed to obtain its empty weight, which will be necessary for calculating the sample weight change during the experiment.

To perform an accurate analysis, it is important to select a representative sample of the polymer. The sample should be free from impurities and properly stored to avoid degradation before the analysis. Additionally, the size and shape of the sample can influence the results, so it is recommended to follow any specific guidelines provided by the instrument manufacturer or testing standards.

Once the sample is prepared, it should be carefully transferred into the TGA crucible. The sample should be evenly distributed within the crucible to ensure uniform heating during the analysis. It is essential to avoid any spillage or contamination, as it can affect the weight measurements and result in inaccurate data.

Before starting the experiment, the TGA instrument should be properly set up. This involves calibrating the instrument using suitable reference materials, setting the desired temperature ramping profile, and verifying the stability and accuracy of the instrument. Calibration ensures the reliability of the instrument's measurements and allows for accurate interpretation of the results.

With the sample loaded and the instrument set up, the TGA experiment can be initiated. The crucible containing the sample is placed into the TGA instrument, and the temperature ramping process begins. The weight changes of the sample are continuously recorded as the temperature increases. These weight changes represent the thermal degradation or stability of the polymer, providing valuable information about its behavior under different temperature conditions.

After completing the TGA experiment, the obtained results need to be analyzed and interpreted. The weight loss or gain of the sample at different temperatures indicates the occurrence of various thermal degradation events. By comparing the results with reference materials or known degradation mechanisms, valuable insights can be gained regarding the polymer's stability, decomposition temperatures, and potential applications.

Several factors can influence the TGA results, and it is important to consider them during the analysis. Environmental factors, such as humidity or the gas atmosphere in the TGA instrument, can affect the thermal behavior of polymers. Sample characteristics, including purity, size, and composition, can also impact the results. Additionally, instrument parameters like the heating rate and sensitivity should be optimized to ensure accurate and reliable measurements.

To obtain meaningful and reproducible TGA results, it is recommended to follow standardized testing protocols and employ proper data analysis techniques. Adhering to established guidelines enhances the reliability and comparability of the results obtained from different laboratories. Additionally, ensuring the reproducibility of the analysis through careful sample preparation and instrument calibration is crucial for obtaining accurate data.

Analyzing the thermal stability of polymers is vital for understanding their behavior under different temperature conditions. TGA analysis using a TGA crucible offers a reliable and widely accepted method for investigating the thermal properties of polymers. By following the proper procedures for TGA sample preparation, instrument setup, and data interpretation, researchers and scientists can gain valuable insights into the thermal stability and degradation behavior of polymers.

Yes, TGA analysis can be applied to various materials, including metals, ceramics, and composites, to investigate their thermal stability and behavior.

TGA crucibles provide a controlled environment for the sample, ensuring accurate measurements of weight changes as a function of temperature.

Yes, TGA analysis can identify the temperature at which the polymer starts to decompose, providing insights into its thermal stability.

The duration of a TGA analysis depends on various factors, including the heating rate and the complexity of the sample. It can range from a few minutes to several hours.

TGA analysis is a non-destructive testing method since it does not alter the sample's chemical structure. The sample can be further analyzed after the TGA experiment if needed.