Your cart is empty.

shop now

Your cart is empty.

shop now

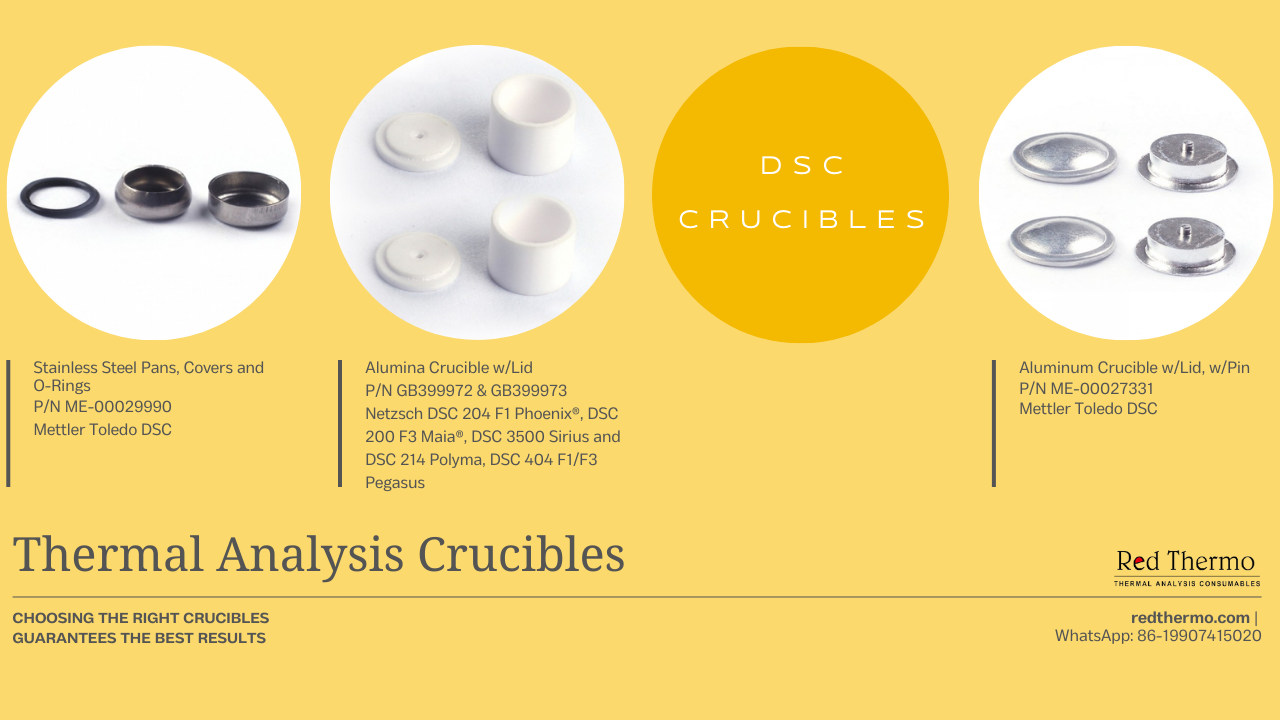

Before we plunge into the realm of contamination, it's imperative to grasp the essence of DSC crucibles and their pivotal role in thermal analysis. DSC crucibles serve as diminutive vessels crafted from materials such as aluminum, platinum, or ceramic. These crucibles cradle both the sample material and the reference material (typically an empty crucible) throughout DSC experiments.

Contamination within DSC crucibles can manifest from a multitude of sources, including prior experiments, subpar cleaning practices, or even the crucible's material composition itself. This contamination has far-reaching consequences, potentially casting doubts on the credibility of your scientific endeavors. Here, we elucidate common contaminants and their repercussions:

Inadequate cleansing of crucibles following previous experiments can result in trace remnants of the prior sample. This, in turn, can engender inaccuracies in baseline measurements, ultimately muddling the interpretation of experimental results.

The very material from which the crucible is crafted can introduce contamination concerns. For example, employing a crucible that reacts with your sample material at elevated temperatures can introduce alterations in your sample's thermal properties, thereby skewing the results you obtain.

Airborne particles and impurities from the laboratory surroundings have the potential to infiltrate the crucible, imperiling the purity of your sample. Such intrusion can lead to discernible shifts in observed melting or crystallization temperatures, further compounding the contamination issue.

Now that we've comprehended the gravity of DSC crucible contamination, let's embark on an exploration of astute strategies aimed at mitigating its impact on your experiments:

Between experiments, make it a priority to meticulously cleanse the crucibles using suitable solvents and cleaning methodologies. Assure the removal of all vestiges of prior sample materials, and, crucially, ensure the crucibles are thoroughly dried to avert any water-related contamination.

Prior to use, institute a practice of pre-heating empty crucibles. This simple step effectively expels residual moisture and contaminants, guaranteeing a pristine baseline for your measurements.

The judicious selection of crucible materials is pivotal. Opt for materials that are compatible with your sample's nature. In instances where your sample is reactive with certain metals, gravitate towards inert materials such as alumina or platinum.

Uphold the sanctity of your laboratory environment by adhering to stringent cleanliness standards. Employ fume hoods and uphold immaculate workspaces to curtail the risk of contamination from airborne sources.

Exercise meticulous care when handling your samples, employing appropriate techniques to prevent spillage or inadvertent contamination during the transfer process to crucibles.

In the domain of thermal analysis and materials science, precision and integrity are the pillars of success. Contamination lurking within DSC crucibles represents a formidable hurdle that could potentially compromise the sanctity of your experiments. By unraveling the origins of contamination and diligently implementing these strategic countermeasures, you can ensure that your DSC experiments yield results that are not only reliable but also profoundly insightful. In the quest for excellence in thermal analysis, attention to detail is paramount, and addressing crucible contamination is a pivotal stride on that journey.

A: To ensure thorough cleansing of DSC crucibles between experiments, use suitable solvents and cleaning methodologies, and make sure to remove all remnants of prior sample materials. It's crucial to ensure that the crucibles are completely dry to prevent water-related contamination.

A: The suitability of DSC crucible materials depends on your sample's nature. In cases where your sample is reactive with certain metals, opt for inert materials such as alumina or platinum.

A: Contamination in DSC crucibles can lead to inaccuracies in baseline measurements, potentially affecting the interpretation of experimental results. It can also cause shifts in observed melting or crystallization temperatures.

A: Preemptive crucible warming helps expel residual moisture and contaminants, ensuring a clean baseline for your DSC measurements. This step is essential to mitigate contamination issues.

A: To maintain a clean laboratory environment and reduce the risk of contamination from airborne sources, use fume hoods and ensure that your workspace is kept immaculate.