Your cart is empty.

shop now

Your cart is empty.

shop now

Proper sealing and preparation of the crucible are critical for accurate DSC analysis. A well-sealed crucible prevents the escape of sample material during the analysis, ensuring reliable results. Additionally, proper preparation eliminates any potential contaminants that could affect the outcome of the analysis. Mastering the technique of sealing and preparing a crucible is essential to obtain precise and reproducible DSC measurements.

The choice of crucible material depends on the specific requirements of your analysis. Common crucible materials include aluminum, platinum, and ceramic. Each material has its advantages and limitations in terms of chemical compatibility, heat resistance, and reactivity. Consider the sample properties, temperature range, and analysis duration when selecting the appropriate crucible material for your experiments.

Before sealing and preparing the crucible, it is crucial to clean it thoroughly to remove any residual contaminants. Start by washing the crucible with a suitable cleaning agent, such as acetone or isopropyl alcohol. Rinse it with distilled water to remove any remaining traces of the cleaning agent. After cleaning, ensure the crucible is completely dry before proceeding to the sealing and preparation steps.

There are various crucible sealing techniques available, each suitable for different types of crucible materials and analysis conditions. Here are three commonly used techniques:

Induction sealing involves the use of electromagnetic induction to heat and seal the crucible. This technique is commonly used for materials with high melting points or in cases where a hermetic seal is required. Induction sealing provides a reliable and robust seal, ensuring minimal sample loss during the analysis.

Welding sealing is often used for crucibles made of materials such as platinum. It involves the fusion of the crucible material using high temperatures to create a strong and leak-proof seal. Welding sealing ensures excellent sample containment and is particularly suitable for high-temperature DSC analysis.

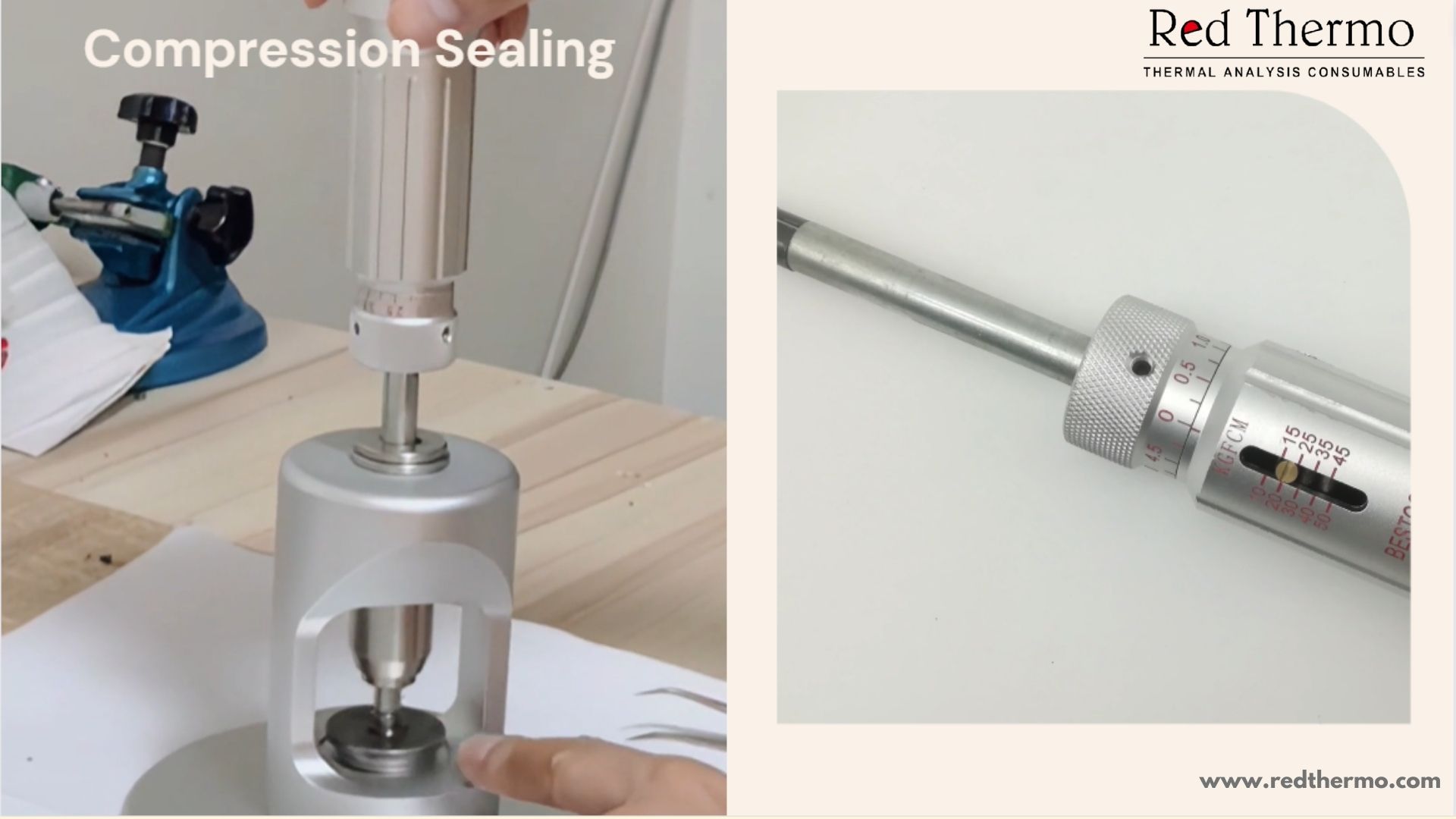

Compression sealing is a versatile technique suitable for various crucible materials. It involves applying pressure to seal the crucible using a sealing apparatus. Compression sealing provides a reliable seal and is relatively easy to perform. However, it is essential to ensure the compression force is uniform to prevent any leakage or sample loss.

Proper loading of the crucible is essential to obtain accurate DSC analysis results. Here are two crucial steps to follow during the crucible loading process:

Accurate weighing of the sample is crucial to ensure precise measurements. Use a calibrated balance to weigh the sample before adding it to the crucible. Carefully add the sample to the crucible, avoiding spillage or contamination. For powders or granular samples, ensure uniform distribution within the crucible.

Air and moisture can affect the thermal properties of the sample during DSC analysis. To minimize their impact, handle the crucible and sample in a controlled environment, preferably a dry atmosphere or a glove box. Avoid prolonged exposure to ambient air and quickly seal the crucible after adding the sample.

Proper labelling and documentation of the crucible are essential for traceability and record-keeping purposes. Label each crucible with relevant information such as sample identification, date, and any additional notes. Maintain a detailed record of the crucible preparation process, including the sealing technique used and any special considerations.

After sealing and preparing the crucible, it is vital to store and handle it appropriately to avoid any damage or contamination. Store the crucibles in a clean and dry environment, away from corrosive substances or excessive heat. Handle the crucibles with clean gloves or specialized tools to prevent fingerprint marks or transfer of contaminants.

When working with crucibles for DSC analysis, it is important to follow these precautions and best practices:

- Always wear appropriate personal protective equipment (PPE) such as gloves and safety glasses.

- Avoid direct contact between the crucible and skin to prevent contamination.

- Handle the crucibles with care to avoid any physical damage that may affect their integrity.

- Clean and inspect the crucibles regularly to ensure their suitability for analysis.

- Follow the manufacturer's guidelines for the specific crucible material and sealing technique.

In case of any issues during the crucible sealing or preparation process, consider the following troubleshooting steps:

- Verify the compatibility of the crucible material with the sample and analysis conditions.

- Check the sealing apparatus or equipment for proper functioning and calibration.

- Ensure the crucible is clean and free from any residual contaminants.

- Review the sealing technique and adjust the parameters if necessary.

- Consult the instrument manual or seek expert advice for complex issues.

Mastering the technique of sealing and preparing a crucible for accurate DSC analysis is crucial for obtaining reliable and precise results. Proper selection of the crucible material, thorough cleaning, appropriate sealing techniques, and careful loading of the sample are key factors in achieving accurate thermal analysis. By following the outlined steps and best practices, you can ensure the integrity of your crucible and obtain meaningful insights from your DSC experiments.

The choice of crucible material depends on factors such as the sample properties, temperature range, and analysis duration. Consider the compatibility of the material with your sample and the specific requirements of your experiment.

Reuse of crucibles depends on the type of material, previous usage, and any potential contamination. It is generally recommended to use new crucibles or thoroughly clean and inspect used ones before reuse.

Yes, proper sealing of the crucible is essential to prevent sample loss and ensure accurate results. Sealing prevents the escape of sample material during the analysis and maintains the integrity of the measurement.

Store crucibles in a clean and dry environment, away from corrosive substances or excessive heat. Handle them with care to avoid any physical damage or contamination.

If you encounter inconsistent or unusual results, review the crucible sealing and preparation steps, ensure proper cleaning and handling, and consider the troubleshooting steps mentioned in this article. If the issue persists, consult with experts or the instrument manufacturer for further guidance.