Your cart is empty.

shop now

Your cart is empty.

shop now

Differential Scanning Calorimetry (DSC) is a technique that employs independently controlled platinum heaters to measure the power necessary to maintain the same temperature profiles in sample and reference cells (as shown in the accompanying figure). The difference in power required provides a direct measure of the heat evolution of the sample. This heat evolution can vary according to the sample, its thermal history, or the type of reaction being observed. For instance, the exothermic peak that is observed when cooling a sample from the liquid state indicates solidification and the release of latent heat. This power difference can also be used to measure other parameters, such as the specific heat of the material, through two methods described later in this instruction set. Careful attention must be taken during all sample runs to ensure reliability. With the level of detail increasing with the sensitivity of the measurement, the specific heat measurements are particularly sensitive.

The importance of reproducible baselines when conducting thermal measurements cannot be overstated. Without consistency, it is difficult to accurately assess the enthalpies of a reaction. Reversible reactions require a second run under the same conditions to acquire a baseline, whereas an irreversible reaction can be cycled through the same temperature profile and the second cycle can be used as the baseline. To ensure accuracy, the system should be calibrated regularly. You can find more information about calibration in the official instructions from Perkin Elmer.

1. Gas Flow

The Diamond DSC uses two gases, UHP Argon and Nitrogen. Argon is used as a cover gas which flows at a slow rate (20 ml/min) over the sample while operating. Nitrogen is utilized as a Deck Hand to flush the cover, reducing condensation and flushing out the ambient oxygen from the cover area once it is sealed.

Regulator Settings | ||

Gas type (Airgas keyword) | Tank Regulator | Instrument Regulator |

Nitrogen (NI 300) | 8 psi | 7 psi |

Argon (AR UHP300) | 20 psi | 20 mL/min |

The nitrogen tank regulator needs to be set above 7 psi, but as low as possible. The nitrogen instrument regulator is located on the back right side, and is adjusted with a black knob. When the instrument is not in use, make sure to turn off the nitrogen. The flow rate is high enough that the tanks will be drained quickly. The argon flow is managed by a restrictor piece. By setting the regulator gauge to 20 psi, a flow rate of 20 mL/min is achieved. The standard Ar flow rate is set on the instrument, and should not be changed from the 20 mL/min setting. The Airgas keyword is provided for easy ordering. It is hoped that the listed numbers will not be modified often; if they do, please update them.

2. Sample Size and Sample Pans

The size of your sample may differ depending on what you are researching. For general non-isothermal runs, the standard sample mass is 5 mg. If you are using high heating rates, you should reduce the sample size to 1.5-3 mg to avoid thermal gradients. If the heating rate is lower, it is possible to use larger sample sizes, but you need to be aware that thermal gradients may be present. If you are only using the DSC as a chamber to anneal smaller samples at specific temperatures, there is no minimum sample mass; however, you cannot accurately measure the heat evolution unless you know the actual mass. Moreover, samples should be as flat as possible. Therefore, placing a ridged spherical sample in the pan is not advisable.

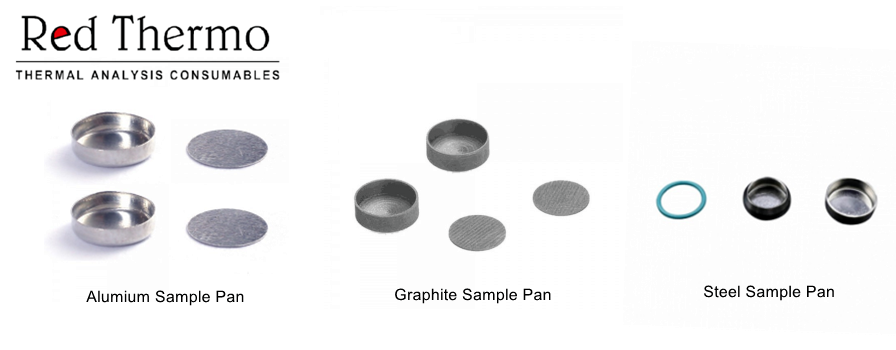

We have a variety of sample pans available, with the standard assembly being composed of pure aluminum. Your sample is placed in the pan, with the cover then put on top, and the assembly is crimped down (if using copper or aluminum). Additionally, we offer copper, steel, gold, platinum, and graphite sample pans. The selection of a certain pan is based on the reactivity of the sample, the temperature range desired, and in some cases pressure.

Sample Pan Summary | ||

Pan Type | Temperature Range | Reactivity |

Aluminum | -50 to 600 | Moderate |

Copper | -50 to 725 | Moderate |

Steel | -50 to 725* | Low |

Gold | -50 to 725 | Very Low |

Platinum | -50 to 725 | Very Low |

Graphite | -50 to 725 | Very Low* |

The reactivity of all pan materials may vary depending on the composition of your sample. Steel pans can be fitted with a polymer o-ring for high-pressure samples that require degassing. However, these should not be heated above 250°C. Gold, platinum and graphite pans are generally designed to be reused, so please take special care when inserting or removing them from the instrument and DO NOT crimp them. Additionally, be mindful of the potential for carbide formation when using graphite pans for samples.

3. Initiating the instrument

1) Turn on the gas (N2 and Ar). Examine the regulators to make certain there is enough gas for your operations.

2) Ensure that the DSC apparatus is activated.

3) Begin running the program and activate the Diamond DSC.

4) Make sure the cover heater and cover gas are turned on by using the buttons located on the right side of the DSC's user interface.

5) Activate the chiller. Let it cool to -80°C before initiating your experiments.

6) Submit your race entry (refer to the below guidelines for more information on this)

Be sure to confirm that the cover of the chiller is able to rotate freely after switching on the machine. Test the cover's movement at temperatures of -20°C, -30°C, -40°C, and -60°C. If it still rotates easily at -60°C, it will be ready to use when the temperature drops to approximately -80°C. Keep in mind that the chiller's display will not include a negative sign. The temperature will start at room temperature and once it passes zero, it will be displaying negative numbers.

4. Troubleshooting

1) The most common issue when beginning the machine is the cover becoming frozen shut, which is most likely to take place during the humid summer season, but is not exclusive to this time period. If this happens, the chiller must be turned off to allow the cover to thaw.

2) One should be extremely cautious when inserting or removing a sample. The most frequent type of harm is denting the top of the platinum furnace cover. However, if this does occur, a tool is available to restore it to its original shape.