Your cart is empty.

shop now

Your cart is empty.

shop now

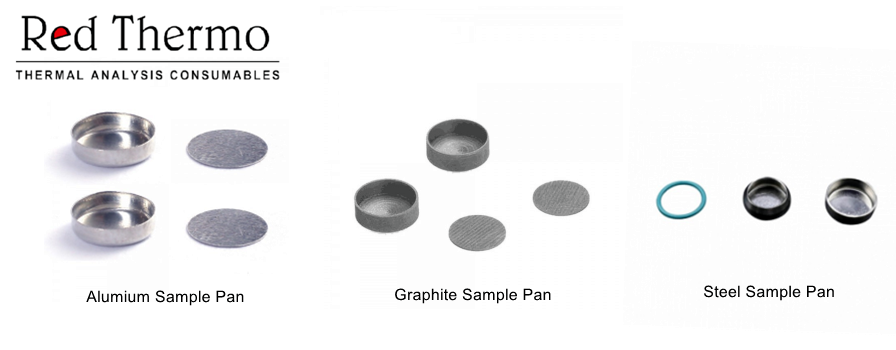

DSC sample pans are typically made from metal, ceramic, or polymer materials. The choice of material depends on the properties of the sample being measured, as well as the temperature range and atmosphere of the measurement. For example, ceramic sample pans are often used for high-temperature measurements in oxidizing or reducing atmospheres, while metal sample pans are more suitable for low-temperature measurements in inert atmospheres.

One recent development in DSC sample pan technology is the use of novel materials for improved performance. For example, researchers have investigated the use of graphene-based materials as DSC sample pans due to their high thermal conductivity, low mass, and chemical inertness. Other materials being explored include carbon nanotubes, metallic glasses, and refractory alloys.

In addition to new materials, researchers have also explored new designs for DSC sample pans to improve their performance and usability. One example is the use of microfabrication techniques to create miniaturized sample pans, which can reduce sample size and improve sensitivity. Another example is the development of sample pans with integrated thermocouples, which can provide more accurate temperature measurements and reduce measurement error.

As with any technology, advances in manufacturing processes have also played a role in improving DSC sample pan performance and reducing costs. One example is the use of additive manufacturing techniques such as 3D printing, which can create complex geometries and reduce material waste. Other improvements include the use of automated assembly processes and quality control measures to ensure consistent and reliable sample pans.

DSC sample pans are used in a wide range of applications, including materials science, pharmaceuticals, and food science. In materials science, DSC is often used to study phase transitions and thermal stability of polymers, composites, and metals. In pharmaceuticals, DSC is used to study drug-polymer interactions and drug stability. In food science, DSC is used to study the melting behavior of fats and oils, and to monitor changes in food texture and shelf life.

Looking to the future, there are several exciting directions in DSC sample pan technology. One area of research is the development of DSC sample pans with improved sensitivity and resolution, which can allow for more detailed characterization of materials. Another area is the integration of DSC with other analytical techniques, such as mass spectrometry or Raman spectroscopy, to provide complementary information about sample composition and behavior.

DSC sample pans are a critical component of differential scanning calorimetry, and advancements in their technology have allowed for improved performance and expanded applications. With new materials, designs, and manufacturing processes being explored, the future of DSC sample pan technology looks bright.

1. What is a DSC sample pan?

Ans: DSC sample pan is a component of differential scanning calorimetry that holds the sample and reference materials during the measurement.

2. What are DSC sample pans made of?

Ans: DSC sample pans can be made of metal, ceramic, or polymer materials, depending on the properties of the sample being measured and the measurement conditions.

3. What are the benefits of using new materials for DSC sample pans?

Ans: New materials such as graphene-based materials and carbon nanotubes can offer high thermal conductivity, low mass, and chemical inertness, which can improve the performance of DSC sample pans.

4. How can new designs improve DSC sample pan performance?

Ans: New designs such as miniaturized sample pans or sample pans with integrated thermocouples can improve sensitivity and accuracy of measurements, and make the instrument more user-friendly.

5. What are some applications of DSC sample pans?

Ans: DSC sample pans are used in materials science, pharmaceuticals, and food science to study phase transitions, thermal stability, drug-polymer interactions, and melting behavior of materials.