Your cart is empty.

shop now

Your cart is empty.

shop now

Content Table

1. Introduction | 5. Comparing Platinum and Alumina Crucibles - Thermal Stability and Resistance - Chemical Compatibility - Cost and Accessibility - Advantages and Disadvantages |

2. Understanding TGA Crucibles - Definition and Purpose - Importance of Crucible Materials | 6. Choosing the Right Crucible for TGA |

3. Platinum Crucibles - Characteristics and Benefits - Applications and Suitability | 7. Conclusion |

4. Alumina Crucibles - Characteristics and Benefits - Applications and Suitability | 8. FAQs 1. Can I reuse platinum and alumina crucibles? 2. Are there any alternatives to platinum and alumina crucibles? 3. How do I clean and maintain TGA crucibles? 4. Can I use platinum crucibles for high-temperature applications? 5. Is the alumina crucible suitable for corrosive environments? |

Thermogravimetric analysis (TGA) is a technique used to measure a sample's weight changes as a function of temperature or time. It provides valuable insights into various material properties, such as thermal stability, decomposition, and moisture content. A crucible is required to hold the sample during the analysis to perform TGA experiments. The choice of crucible material can significantly impact the accuracy and reliability of the results.

A TGA crucible is a container designed to withstand high temperatures and chemical reactions while holding the sample. It should be inert to the material being analyzed and provide accurate weight measurements. The crucible acts as a controlled environment for the sample, allowing precise observation of weight changes throughout the analysis.

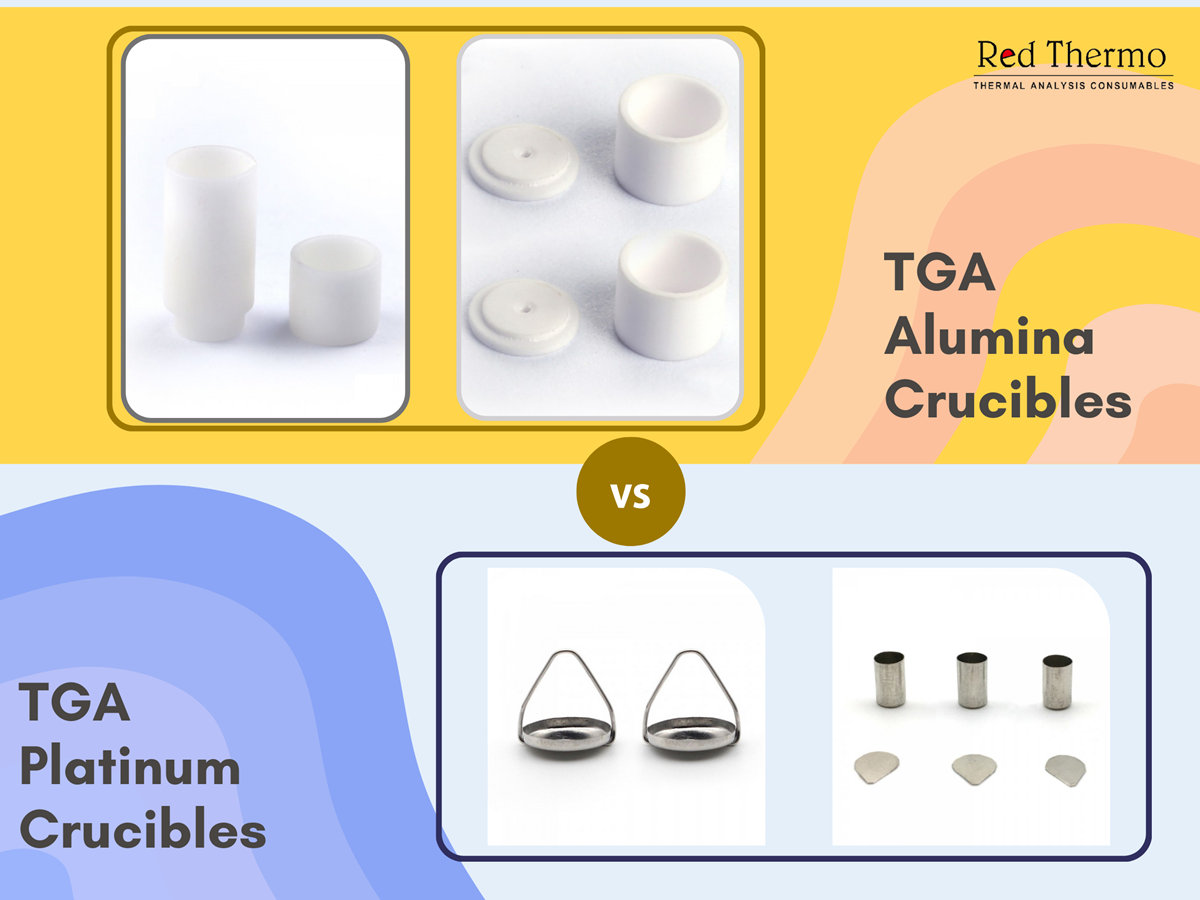

The choice of crucible material is crucial for obtaining accurate TGA results. Different materials offer properties such as thermal stability, chemical compatibility, and resistance to reactions or contaminations. Two popular crucible materials used in TGA experiments are platinum and alumina.

Platinum crucibles are widely recognized for their exceptional thermal and chemical properties. They are suitable for high-temperature applications and offer excellent resistance to corrosion and oxidation. Platinum crucibles are often preferred in TGA experiments where precise measurements at elevated temperatures are required.

Platinum crucibles exhibit remarkable thermal stability, allowing them to withstand extreme temperatures without deformation or degradation. They also possess high chemical inertness, making them compatible with various substances. This inertness ensures minimal interference with the sample, resulting in accurate weight measurements. Additionally, platinum crucibles have low adhesion properties, reducing the chances of the sample sticking to the crucible.

Platinum crucibles find applications in various fields, including pharmaceuticals, materials research, and environmental analysis. They are particularly useful for analyzing high-temperature reactions, such as pyrolysis, combustion, and thermal decomposition. Due to their durability and resistance to aggressive environments, platinum crucibles are well-suited for experiments involving corrosive substances or reactive samples.

Alumina, also known as aluminum oxide (Al2O3), is another commonly used crucible material in TGA experiments. Alumina crucibles offer distinct advantages and are suitable for a wide range of applications.

Alumina crucibles exhibit excellent thermal stability and can withstand high temperatures. They are chemically inert and resistant to most acids, bases, and solvents. Alumina crucibles are also electrically insulating, making them suitable for electrical heating experiments. Additionally, they have good thermal conductivity, facilitating efficient heat transfer during the analysis.

Alumina crucibles are widely used in TGA experiments that involve the analysis of inorganic materials, ceramics, minerals, and metals. They are particularly suitable for applications where resistance to thermal shock is essential. Alumina crucibles find applications in industries such as metallurgy, ceramics, and geology.

When selecting a crucible material for TGA experiments, several factors need to be considered. Let's compare platinum and alumina crucibles based on key parameters:

Platinum crucibles exhibit exceptional thermal stability and can withstand temperatures as high as 1,500°C without deformation. Alumina crucibles, on the other hand, can typically handle temperatures up to 1,800°C. Both materials offer excellent resistance to thermal shock, ensuring reliable performance during heating and cooling cycles.

Platinum crucibles are highly resistant to corrosion and oxidation, making them compatible with a wide range of chemicals and reactive substances. Alumina crucibles also exhibit excellent chemical inertness and are resistant to most acids, bases, and solvents. However, they may not be suitable for certain highly corrosive materials or reactions involving fluorine-containing compounds.

Platinum crucibles are more expensive than alumina crucibles due to the high cost of platinum as a precious metal. Alumina crucibles, on the other hand, are relatively more affordable and readily available. The choice between the two materials often depends on budget constraints and specific experimental requirements.

Platinum crucibles offer superior thermal stability, chemical resistance, and durability. However, their high cost and limited availability can be drawbacks. Alumina crucibles provide excellent performance at a more affordable price but may not be suitable for extremely high-temperature applications or certain corrosive environments.

When selecting a crucible for TGA experiments, it is crucial to consider the specific requirements of your analysis. Factors such as temperature range, sample type, chemical compatibility, and budget constraints should be considered. Consultation with experts or crucible manufacturers can provide valuable guidance in choosing the most suitable crucible material for your experiments.

In summary, the choice of crucible material in TGA experiments plays a vital role in obtaining accurate and reliable results. Platinum crucibles offer exceptional thermal stability and chemical resistance, making them ideal for high-temperature applications. On the other hand, Alumina crucibles provide good thermal stability, chemical inertness, and affordability, catering to a wide range of applications. By carefully considering the specific requirements of your analysis, you can select the most suitable crucible material to ensure the success of your TGA experiments.

1. Can I reuse platinum and alumina crucibles?

Both platinum and alumina crucibles can be reused multiple times if they are properly cleaned and maintained. However, inspecting them for any signs of wear or damage before reuse is essential to ensure accurate results.

2. Are there any alternatives to platinum and alumina crucibles?

Yes, alternative crucible materials are available, such as quartz, graphite, and certain ceramics. The choice of material depends on the specific requirements of your analysis and the compatibility with the sample being tested.

3. How do I clean and maintain TGA crucibles?

Cleaning TGA crucibles typically involves removing any residual sample material by washing with appropriate solvents or acids, followed by thorough rinsing and drying. Specific cleaning procedures may vary depending on the crucible material and the type of contamination.

4. Can I use platinum crucibles for high-temperature applications?

Yes, platinum crucibles are suitable for high-temperature applications due to their exceptional thermal stability. They can withstand elevated temperatures without deformation or degradation.

5. Is the alumina crucible suitable for corrosive environments?

Alumina crucibles exhibit good chemical inertness and resistance to most acids, bases, and solvents. While they are generally suitable for corrosive environments, it is essential to consider the specific corrosive substances and their compatibility with alumina.