Your cart is empty.

shop now

Your cart is empty.

shop now

TGA crucibles are small containers that hold the sample during the TGA analysis. They are typically made of materials that exhibit excellent chemical resistance, high-temperature stability, and low reactivity with the sample being analyzed. These crucibles must be carefully selected to ensure accurate and reliable results in food analysis.

TGA (Thermogravimetric Analysis) crucibles come in various materials, each offering unique advantages and suitability for different applications in food analysis. Let's explore some of the commonly used crucible types, including aluminum crucibles, and their characteristics:

Aluminum crucibles are widely employed in TGA analysis due to their versatility and cost-effectiveness.

Alumina crucibles, made from aluminum oxide (Al2O3), are popular in TGA analysis due to their excellent thermal stability.

Platinum crucibles are renowned for their exceptional chemical resistance, making them ideal for analyzing corrosive samples.

Advantages of using TGA crucibles include

- Accurate measurement of weight changes during thermal analysis.

- Compatibility with a variety of sample types and sizes.

- Availability of different crucible materials for specific applications.

- Cost-effective options for routine analysis.

- Potential reactivity between the crucible material and certain sample components.

- Limited temperature range for some crucible materials.

- Fragility or susceptibility to damage in certain cases.

When selecting a TGA crucible for food analysis, several factors should be considered:

Sample Compatibility

Ensure that the crucible material is chemically inert and does not react with the sample components, which could affect the analysis results.

Temperature Range

Verify that the crucible can withstand the desired temperature range for the analysis without undergoing structural changes or degradation.

Choose a crucible compatible with the specific analysis method employed, such as thermogravimetry, differential thermal analysis, or evolved gas analysis.

Consider the appropriate crucible size to accommodate the sample and allow for accurate weight measurements.

To ensure accurate and reliable TGA analysis in food analysis, follow these best practices:

- Preheat the crucible to remove any residual moisture or contaminants before adding the sample.

- Use an appropriate balance to measure the sample accurately.

- Minimize exposure of the crucible to ambient air during weighing and sample preparation.

- Perform baseline measurements with an empty crucible to account for any weight changes not related to the sample.

- Employ proper heating rates and temperature programs based on the sample characteristics and analysis objectives.

TGA crucibles find extensive applications in food analysis, including:

- Determination of moisture content and volatiles in food products.

- Evaluation of the thermal stability of fats, oils, and emulsions.

- Characterization of food additives, such as antioxidants, preservatives, and colorants.

- Investigation of the degradation kinetics of food ingredients during processing or storage.

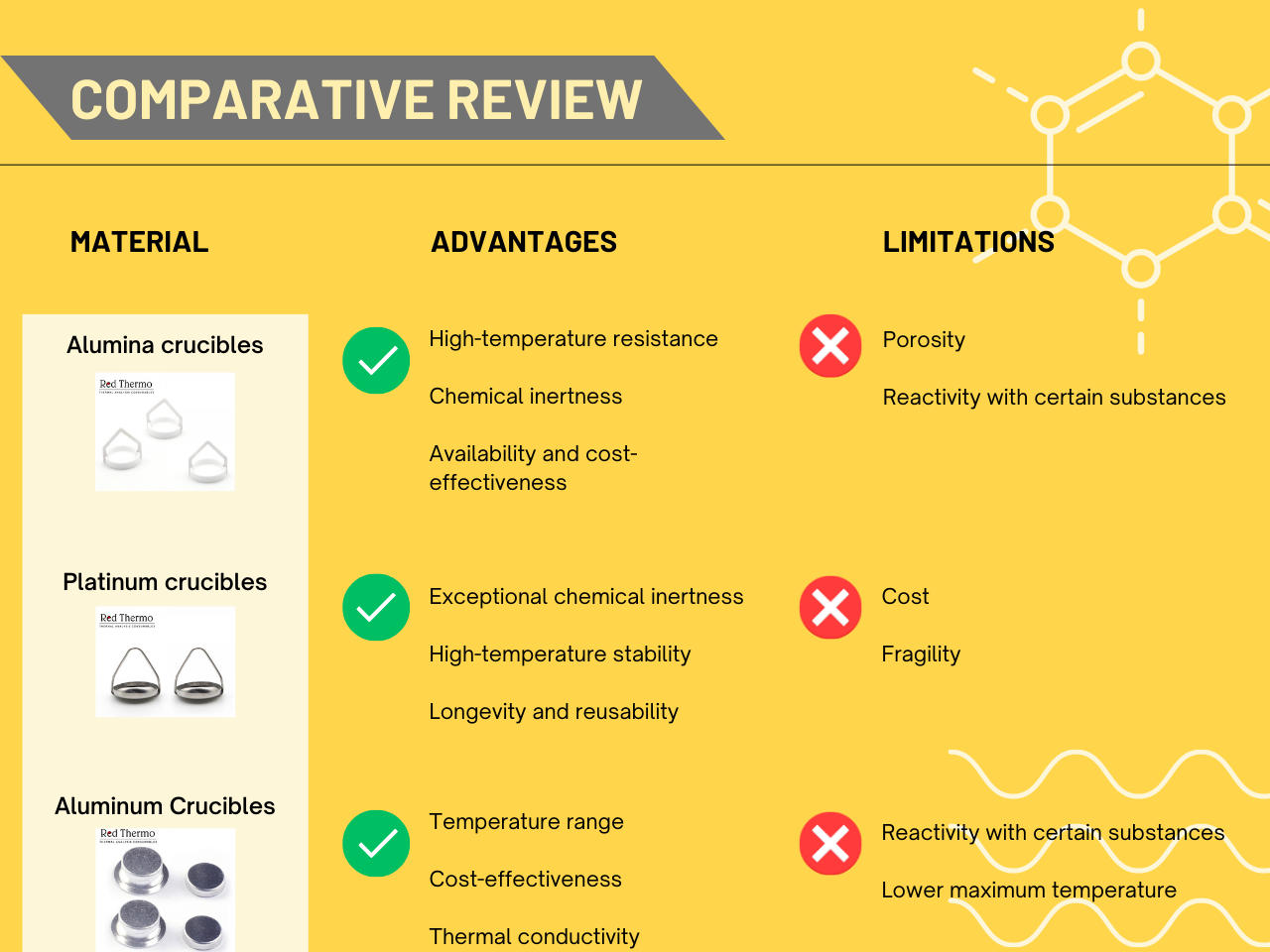

This section will compare and contrast different TGA crucibles based on their material properties, temperature range, reactivity, cost, and suitability for specific food analysis applications. By examining the advantages and limitations of each crucible type, researchers and analysts can make informed decisions when selecting crucibles for their specific analytical needs.

Alumina crucibles are widely used in TGA analysis due to their excellent thermal stability and resistance to high temperatures. They offer the following advantages:

- High-temperature resistance: Alumina crucibles can withstand temperatures up to 1600°C, making them suitable for a wide range of food analysis applications.

- Chemical inertness: Alumina is generally chemically inert, minimizing the risk of reactions between the crucible material and food components.

- Availability and cost-effectiveness: Alumina crucibles are readily available and relatively cost-effective compared to other crucible materials.

However, alumina crucibles have some limitations:

- Porosity: Alumina crucibles may have a degree of porosity, which can lead to the adsorption or absorption of volatile components during analysis.

- Reactivity with certain substances: Alumina may react with certain acidic or alkaline substances present in food samples, potentially affecting the accuracy of the analysis.

Platinum crucibles offer superior chemical resistance, making them ideal for analyzing samples that contain corrosive substances. They provide the following advantages:

- Exceptional chemical inertness: Platinum is highly resistant to corrosion and reactions with most chemicals, ensuring accurate analysis results.

- High-temperature stability: Platinum crucibles can withstand temperatures up to 1700°C, making them suitable for high-temperature food analysis applications.

- Longevity and reusability: Platinum crucibles can be reused multiple times with proper care and handling, making them a cost-effective choice in the long run.

However, platinum crucibles have some limitations:

- Cost: Platinum crucibles are relatively expensive compared to other crucible materials, making them less accessible for routine analysis.

- Fragility: Platinum is a soft metal, making the crucibles susceptible to damage if mishandled or subjected to mechanical stress.

Aluminum crucibles offer several advantages for TGA analysis in food applications. They provide the following benefits:

- Temperature range: Aluminum crucibles can withstand temperatures up to 900°C, making them suitable for many food analysis processes.

- Cost-effectiveness: Aluminum crucibles are more affordable compared to platinum crucibles, making them a practical choice for routine analysis.

- Thermal conductivity: Aluminum has good thermal conductivity, allowing for efficient heat transfer during analysis.

However, aluminum crucibles have some limitations:

- Reactivity with certain substances: Aluminum may react with acidic or alkaline food components, leading to potential contamination or reactions that affect the accuracy of the analysis.

- Lower maximum temperature: Compared to platinum or alumina crucibles, aluminum crucibles have a lower maximum temperature limit, limiting their suitability for high-temperature applications.

By considering the advantages and limitations of each crucible type, analysts can choose the most appropriate crucible material for their specific food analysis requirements.

To provide a comprehensive understanding of the practical applications of TGA crucibles in food analysis, we will explore several case studies that highlight their versatility and effectiveness in different scenarios.

In this case study, we aim to determine the moisture content in various baked goods using TGA analysis. We selected alumina crucibles for this analysis due to their wide temperature range and compatibility with food samples.

First, we accurately weighed the samples, including bread, cookies, and pastries, using a precision balance. The samples were then placed in preheated alumina crucibles. The TGA analysis was performed by subjecting the samples to a controlled temperature increase from room temperature to 150°C.

By monitoring the weight loss during heating, we were able to determine the moisture content in the baked goods. The results showed variations in moisture content among the different products, providing valuable insights for quality control and recipe optimization.

In this case study, we focused on evaluating the thermal stability of different cooking oils using TGA analysis. Platinum crucibles were chosen for their excellent chemical resistance to corrosive substances.

We prepared small samples of various cooking oils, including olive oil, coconut oil, and sunflower oil, and loaded them into preheated platinum crucibles. The TGA analysis involved heating the samples at a controlled rate from room temperature to 400°C.

By monitoring the weight loss and thermal degradation of the oils, we gained insights into their stability and susceptibility to decomposition at elevated temperatures. This information is crucial for understanding the optimal cooking conditions and shelf life of different oils.

In this case study, we aimed to characterize the thermal behavior of food additives commonly used in processed foods. Ceramic crucibles were selected as cost-effective alternatives to platinum crucibles, offering good chemical resistance and high-temperature stability.

We prepared samples containing food additives such as antioxidants, preservatives, and colorants and placed them in preheated ceramic crucibles. The TGA analysis involved subjecting the samples to a gradual temperature increase from room temperature to 800°C.

By analyzing the weight loss and decomposition patterns of the additives, we obtained valuable information about their thermal stability, degradation products, and potential effects on food quality and safety.

These case studies demonstrate the versatility and effectiveness of TGA crucibles in a wide range of food analysis applications. Selecting appropriate crucibles based on the specific analysis objectives and sample characteristics ensures accurate and reliable results, contributing to advancements in food science and quality control.

TGA crucibles play a vital role in food analysis, enabling researchers and analysts to determine the composition and thermal stability of various food components. By selecting suitable crucible material and employing best practices, accurate and reliable results can be obtained. The comparative review of TGA crucibles provides a valuable resource for professionals in the field, aiding in selecting appropriate crucibles for specific food analysis applications.

1. Q: Can TGA crucibles be reused?

A: It depends on the specific crucible material and its condition. Some crucibles, such as platinum or quartz, can be reused after proper cleaning and inspection.

2. Q: Are TGA crucibles compatible with liquid samples?

A: TGA crucibles are primarily designed for solid or powdered samples. However, certain crucibles can accommodate liquid samples with appropriate sample holders or containment methods.

3. Q: What is the typical temperature range for TGA analysis?

A: The temperature range varies depending on the crucible material and the analysis objectives. It can typically range from room temperature up to 1,500°C or higher.

4. Q: Can TGA crucibles be used for quantitative analysis?

A: TGA analysis provides valuable information about weight changes and thermal events but may not directly yield quantitative data. Additional calibration or comparative methods are often required for precise quantitative analysis.

5. Q: Is TGA analysis suitable for analyzing volatile components in food?

A: Yes, TGA analysis coupled with suitable crucibles, such as quartz crucibles, can effectively analyze volatile components in food samples by monitoring weight changes as a result of volatilization.