Your cart is empty.

shop now

Your cart is empty.

shop now

The Q600 has the ability to measure weight alteration (TGA) and correct differential heat flow (DSC) on the same specimen from room temperature up to 1,500 ˚C. It utilizes a tested horizontal dual beam design with computerized beam growth adjustment and is capable of analyzing two TGA specimens all at once. The DSC heat flow information is adjusted in real-time using the instantaneous sample weight at any given temperature.

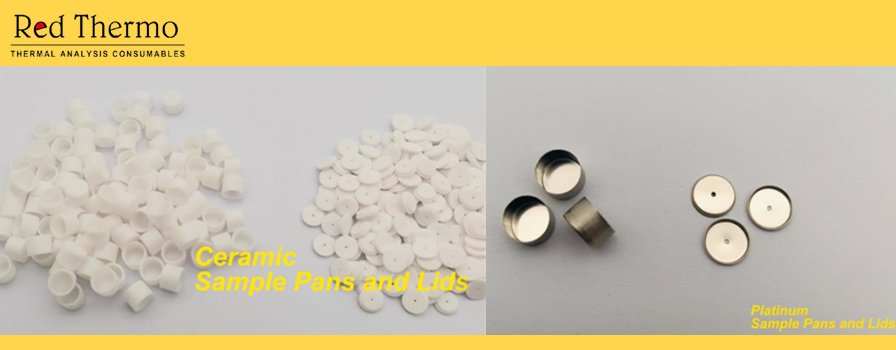

To perform a simultaneous measurement of weight change (TGA) and differential heat flow (DSC) on the same sample from ambient to 1,500℃, great attention must be given to the preparation of the sample. It is necessary that the sample is consistent in size and shape and is divided into smaller parts to enable accurate measurements. The sample must be placed in a platinum sample pan or a ceramic sample pan and the pan must be sealed tightly to make sure that no air or moisture can get in or out during the experiment.

Q600 users can access platinum pans (40μL and 110 μL) or ceramic cups (40μL and 90 μL). The platinum pans are best for operations up to 1,000 ˚C and are characterized by their inertness and ease of cleaning. Ceramic cups, on the other hand, are appropriate for temperatures up to 1,500 ˚C and for samples that don't react with platinum.

The test plan for the simultaneous measurement of TGA and DSC with SDT Q600 should include the following steps:

1. Pre-test sample preparation: The sample should be placed into a platinum sample pan or a ceramic sample pan, sealed tightly to ensure that no air or moisture can enter or leave the sample during the testing process.

2. Pre-test calibration: The sample should be calibrated in order to ensure accuracy of the results. This should include setting the temperature and pressure to the desired levels and ensuring that the sample pan is level.

3. Test set-up: The sample should be placed on the thermal analysis system and the temperature and pressure should be set to the desired levels.

4. Data collection: The thermal analysis system should be set to collect data at various temperatures and times. This data should include the weight change (TGA) and the differential heat flow (DSC) of the sample.

5. Analysis of results: The collected data should be analyzed to determine the presence of any crystal transitions, melting, solidification, purity, evaporation, adsorption of water and crystallization of water content, sublimation, adsorption, desorption, absorption, glass transition, liquid crystal transition, change of thermal capacity, decomposition, combustion, polymerization, solidification, catalytic reaction, and dynamics of the sample.