Your cart is empty.

shop now

Your cart is empty.

shop now

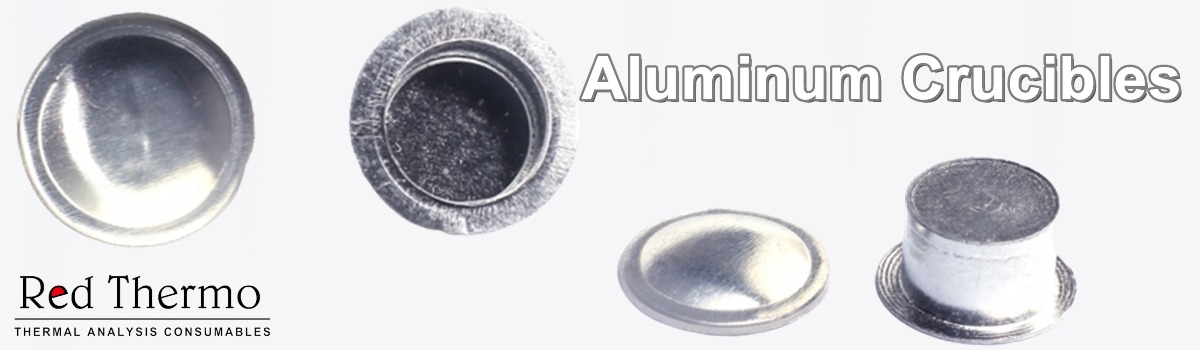

They are a type of laboratorycrucible often used as containers in thermoanalytical measurements. They are preferred over other materials due to their ability to withstand higher temperatures and protect the sample during thermal analysis experiments. Additionally, they provide a secure and efficient transfer of heat to the sample.

A crucible for thermal analysis is a container

used to measure samples during thermoanalytical measurements. Aluminum is a

popular material for these types of crucibles because it has excellent

heat-conducting and corrosion-resistant properties, making it ideal for use in

high-temperature applications. Additionally, aluminum cruicbles that come in

contact with chemicals don't react, meaning they won't contaminate the sensor

or sample being measured. Overall, these properties make aluminum crucibles an

ideal choice for thermal analysis applications.

Aluminum crucibles are a popular choice for

many laboratory applications. The benefits of using aluminum crucibles include

the ability to withstand high temperatures, its resistance to corrosion, and

its affordability. Crucibles made out of aluminum are lightweight, allowing

them to reach optimal resolution levels. They are lighter than other materials

and can be heated or cooled quickly and they can provide an efficient and

reliable way to contain materials through controlled heating processes.

An aluminum crucible is ideal for labs and

industrial processes due to its ability to deliver high purity results. This is

because it does not interact with the sample, maintaining its integrity, as

well as providing reliable and accurate measurements. An Aluminum crucible is

an important industrial tool that is typically used to contain and transfer

high temperature materials. Made of aluminum, the material is chosen for its

excellent thermal conductivity and exceptional form stability when exposed to

extreme temperatures. When investing in an aluminum crucible, flatness should

be considered to guarantee perfect thermal contact and help avoid any

irregularities. Aluminum crucibles are great for large-volume materials, as

this increases the overall sensitivity of the experiment.

Aluminum crucibles are used in laboratories and industrial production for heating materials such as metals and other substances for melting, refining or alloying purposes. They come in a wide range of sizes, shapes and diameters depending on the needs of a particular application. Aluminum crucibles, ranging in volume from 40 to 160 micrometers (µL), are special containers designed specifically to support high temperature processing. These crucibles are often used as vessels for melting metals or glasses and can withstand temperatures of up to 2,000 degrees Celsius. Aluminum crucibles are the preferred choice when needing small volume and fast heat-up times. These containers made of aluminum typically optimize their outputs at volumes of up to 20 microliters, offering excellent signal response and short time constants. For larger applications, copper crucibles are an alternative choice.