Your cart is empty.

shop now

Your cart is empty.

shop now

TGA crucibles, short for Thermogravimetric Analysis crucibles, are specialized containers designed to hold samples during thermogravimetric analysis. This analytical technique involves subjecting materials to controlled temperature changes while measuring their weight changes. The data obtained from TGA experiments provide insights into various material properties such as composition, stability, and thermal behavior.

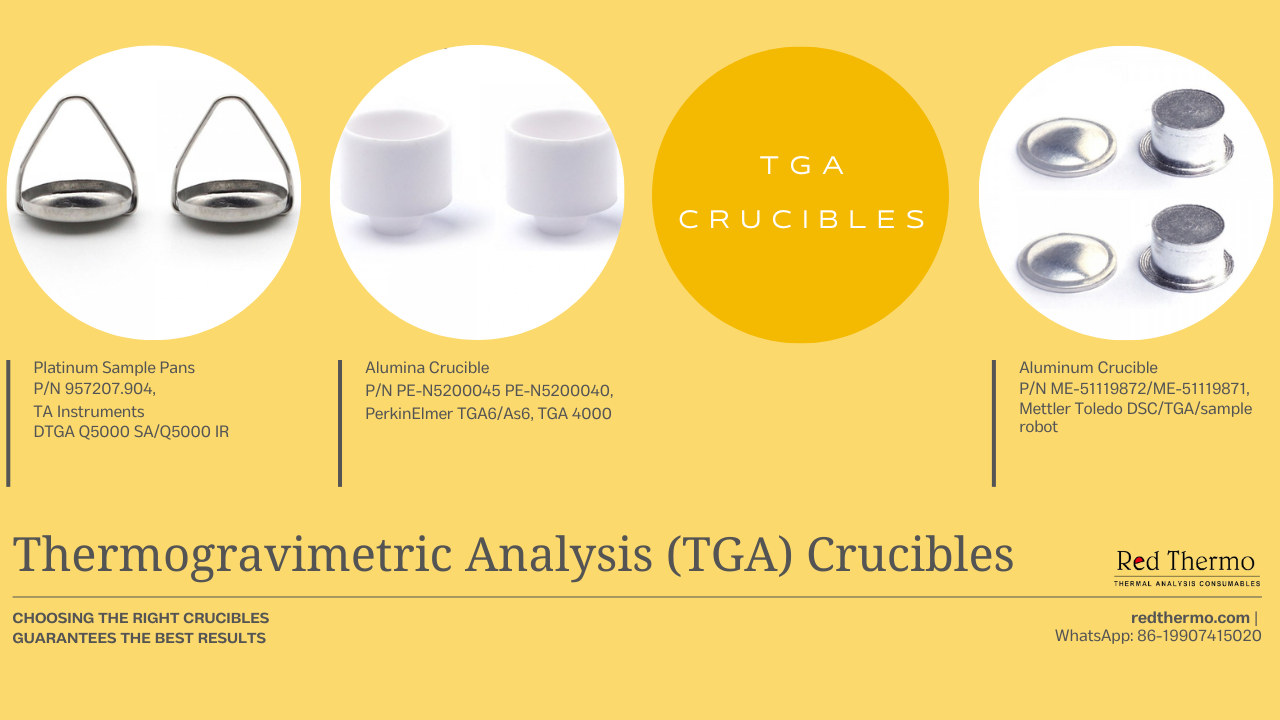

TGA crucibles serve as the vessels that house the samples undergoing analysis. Their composition is chosen to minimize any interference with the sample and prevent contamination. Typically made from materials like alumina, platinum, or ceramic, these crucibles exhibit high thermal stability and chemical inertness. This ensures that any observed weight changes are attributed solely to the sample's characteristics.

The precise measurements obtained through TGA experiments are instrumental in material research. By subjecting a material to controlled temperature increases, researchers can monitor its weight loss or gain as different components react to changing conditions. This data aids in determining thermal transitions, decomposition points, and compositional changes within the material. Such information is crucial in assessing a material's performance, stability, and potential applications.

TGA crucibles play a pivotal role in unraveling a material's thermal behavior. As temperature increases, substances within the sample might undergo phase changes, release gases, or decompose. TGA experiments capture these intricate details, enabling scientists to pinpoint specific temperature ranges at which these transformations occur. This information is essential for industries ranging from polymers to pharmaceuticals, helping optimize processes and ensure product quality.

Materials degrade over time due to various factors, including exposure to heat, moisture, and light. TGA crucibles aid in characterizing degradation patterns by subjecting samples to controlled thermal conditions. Researchers can identify weight losses corresponding to different stages of degradation, which helps in predicting a material's lifespan and recommending appropriate storage or usage conditions.

TGA crucibles play a fascinating role in material research, contributing to the advancement of various fields. From pharmaceuticals to electronics, these crucibles offer insights that influence product development, quality control, and innovation.

In the pharmaceutical industry, the stability of drugs is of paramount importance. TGA crucibles help assess the thermal stability of drug compounds, ensuring they remain effective under different storage conditions. Researchers can identify temperature ranges at which degradation occurs, allowing pharmaceutical companies to formulate products that withstand real-world scenarios.

Polymer industries leverage TGA crucibles to fine-tune material properties. By analyzing weight loss during heating, scientists can determine the thermal transitions of polymers. This information aids in designing polymers with specific melting points, glass transition temperatures, and thermal stability, crucial for applications in packaging, textiles, and more.

TGA crucibles find utility in environmental studies as well. Researchers analyze organic matter like soil, compost, and plant materials to understand decomposition processes. By tracking weight changes at different temperatures, they gain insights into the composition of organic matter and the release of gases during decomposition.

Nanomaterials exhibit unique properties that hold promise in various industries. TGA crucibles assist in studying these materials by revealing weight changes associated with phase transitions and chemical reactions. This information aids in optimizing the synthesis and application of nanomaterials.

Q: How do TGA crucibles contribute to accurate material analysis?

A: TGA crucibles are designed to minimize interference with samples, ensuring that weight changes observed are solely due to the sample's characteristics. This leads to precise and reliable measurement data.

Q: Can TGA crucibles determine a material's thermal transitions?

A: Yes, TGA crucibles are essential in identifying temperature ranges at which materials undergo phase changes, decomposition, or release of gases, providing valuable information about thermal behavior.

Q: What industries benefit from TGA crucible analysis?

A: TGA crucibles find applications in pharmaceuticals, polymers, environmental science, nanotechnology, and more, contributing to product development, material design, and scientific research.

Q: How do TGA crucibles aid in predicting material degradation?

A: TGA crucibles help characterize degradation patterns by monitoring weight loss during controlled thermal conditions. This information assists in predicting a material's lifespan and recommending suitable usage or storage conditions.

Q: Are TGA crucibles chemically inert?

A: Yes, TGA crucibles are typically made from materials like alumina, platinum, or ceramic, chosen for their high thermal stability and chemical inertness to prevent contamination during analysis.

Q: How do TGA crucibles impact nanotechnology research?

A: TGA crucibles are used to study nanomaterials by tracking weight changes during phase transitions and reactions. This aids in optimizing the synthesis and application of nanomaterials.

TGA crucibles are unsung heroes in the world of material research, driving discoveries and innovations across industries. From analyzing drug stability to investigating nanomaterials, their significance cannot be overstated. These unassuming vessels wield the power to unlock the mysteries of materials, offering insights that shape our technological advancements. So next time you encounter a TGA crucible, remember its role in unraveling the secrets of the materials that surround us.