Your cart is empty.

shop now

Your cart is empty.

shop now

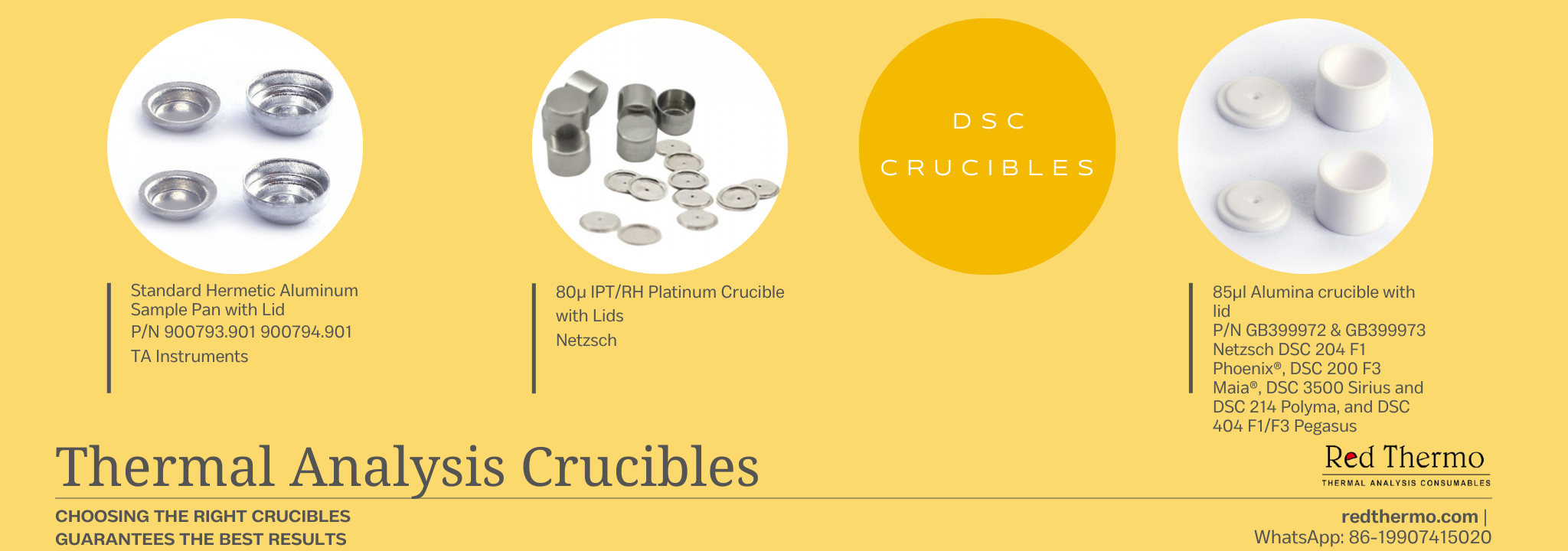

Before delving into the issue of leakages, it's essential to have a clear understanding of the DSC crucible's role in experiments. The DSC crucible is a small container that holds the sample to be analyzed. It is subjected to varying temperatures to measure the sample's heat flow characteristics, including phase transitions, reactions, and more.

One of the primary reasons for crucible leakages is improper sealing. The crucible must be tightly sealed to prevent any gas exchange with the surroundings. Even a minor gap can lead to inaccurate results.

Overfilling the crucible can cause sample spillage, leading to leaks. It's crucial to follow the recommended sample size guidelines provided by the instrument manufacturer.

Physical damage to the crucible, such as cracks or scratches, can compromise its integrity. Regularly inspect the crucibles for any signs of wear and tear.

Incomplete sample preparation, such as uneven distribution of the sample or the presence of foreign materials, can lead to leaks during the experiment.

Rapid changes in temperature can cause the crucible material to expand or contract, potentially creating gaps and causing leaks. Gradual temperature transitions are preferred.

Now that we've identified the common causes of DSC crucible leakages, let's explore effective strategies to prevent them and ensure a smooth experiment.

- Sealing Ritual: Consider sealing your crucibles a sacred ritual in your laboratory. Pay meticulous attention to detail, and use the right tools and techniques. Whether you're using a press or a manual sealing machine, ensure that every seal is airtight.

- Leak Check: Before starting your experiment, perform a leak check. This involves subjecting the sealed crucible to a non-reactive gas and checking for any gas exchange. It's a small step that can save you from major headaches later.

- Size Matters: Remember that bigger doesn't always mean better in DSC experiments. Carefully measure your sample and follow the manufacturer's recommendations. It's like following a recipe; deviations can result in a less-than-perfect outcome.

- Sample Homogeneity: Ensure that your sample is homogenously distributed within the crucible. Uneven distribution can cause pressure imbalances and lead to leaks.

- A Watchful Eye: Make it a routine to inspect your crucibles before use. Look for any signs of wear and tear, no matter how minor. Replacing damaged crucibles promptly is an investment in the reliability of your experiments.

- Clean and Pure: Remove any foreign materials or impurities from your sample. These unwanted elements can react with the crucible material and compromise the integrity of the seal.

- Distribution Matters: Evenly distribute the sample within the crucible. This helps maintain pressure equilibrium during experiments.

- Easy Does It: Slow and steady wins the race when it comes to temperature transitions. Gradual changes reduce stress on the crucible material and minimize the risk of leaks.

In conclusion, addressing common DSC crucible leakages is essential for obtaining accurate and reliable experimental results in dynamic scanning calorimetry. By following the tips outlined in this article, you can significantly reduce the risk of crucible leakages and ensure a leak-free experiment. Remember that attention to detail in crucible handling and sample preparation is key to success in DSC experiments. Incorporating these best practices will undoubtedly contribute to the quality of your research and analyses, allowing you to achieve meaningful insights in materials science and chemistry.