Your cart is empty.

shop now

Your cart is empty.

shop now

Crucible cracking or failure can lead to inaccurate results and data loss, making it crucial to address these problems promptly. Let's explore some effective strategies for troubleshooting and preventing these issues:

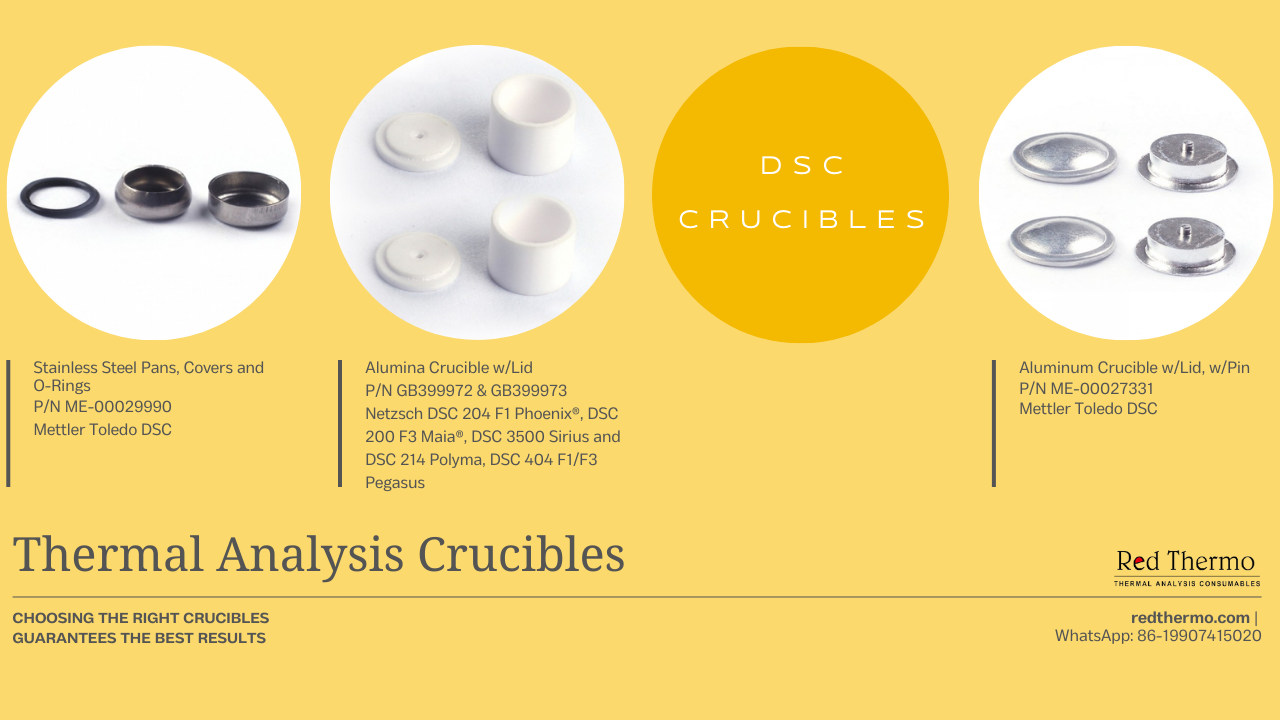

Using the right type of crucible material is essential. Different materials have varying resistance to temperature changes and chemical reactions. Inferior-quality crucibles are prone to cracking under extreme conditions. Opt for high-quality crucibles made from materials like alumina or platinum to minimize the risk of failure.

Improper handling and loading of samples can stress crucibles, leading to cracks. Always handle crucibles with care, avoiding sudden impacts or pressure. When loading samples, ensure they are evenly distributed to prevent uneven stress distribution that can cause cracking.

Gradual Temperature Changes

Rapid temperature changes can cause thermal shock, leading to crucible failure. To avoid this, implement gradual temperature ramps during DSC experiments. Modern DSC instruments often allow for programmable heating and cooling rates, which can help minimize thermal shock.

Overloading crucibles with excessive sample quantities can result in mechanical stress and cracking. Follow the manufacturer's guidelines for recommended sample sizes. Additionally, ensure samples are properly prepared and evenly distributed within the crucible to prevent localized stress.

Before conducting experiments, it's advisable to preheat and condition crucibles. Gradually heating the empty crucible to the desired temperature range before introducing the sample can help alleviate internal stresses and minimize the risk of cracking.

Certain substances can react with crucible materials, leading to degradation and failure. Be aware of the chemical compatibility of your samples and crucible materials. Use protective coatings or alternative crucible materials if necessary.

Frequent maintenance and inspection of crucibles are essential for identifying early signs of wear, damage, or defects. Regularly inspect crucibles for cracks, discoloration, or warping. Replace any damaged crucibles before conducting experiments.

In high-temperature experiments, consider using crucible lids or covers to provide additional protection against thermal shock and contamination. These measures can contribute to extending the lifespan of crucibles and minimizing failure risks.

For more in-depth information about crucible materials and handling techniques, you can refer to reputable sources like Thermo Fisher Scientific(https://www.thermofisher.com/) or NETZSCH Analyzing & Testing(https://www.netzsch-thermal-analysis.com/).

A: It's not recommended to reuse cracked crucibles, as they may compromise experimental results and safety. Replace cracked crucibles with new ones to ensure accurate and reliable data.

A: If you notice cracks forming during an experiment, immediately halt the procedure and allow the crucible to cool down. Replace the cracked crucible with a new one before resuming the experiment.

A: Yes, certain crucible materials like platinum and quartz are better suited for reactive samples due to their chemical resistance. Research and choose a material that aligns with your sample's properties.

A: While complete elimination of thermal shock is challenging, gradual temperature changes and proper preheating can significantly minimize its impact on crucibles.

A: Regular maintenance, careful handling, controlled temperature changes, and using protective measures like lids can help prolong the lifespan of crucibles.

A: Yes, you can use protective coatings like alumina or zirconia to enhance the chemical resistance and longevity of crucibles.

Successfully troubleshooting common issues related to crucible cracking or failure during DSC experiments requires a combination of proper material selection, handling techniques, temperature control, and maintenance practices. By following the strategies outlined in this guide, researchers can enhance the reliability and accuracy of their DSC experiments while minimizing the risk of crucible-related challenges. Remember that careful attention to detail and proactive measures can lead to more successful and productive experimental outcomes.