Your cart is empty.

shop now

Your cart is empty.

shop now

Preparation

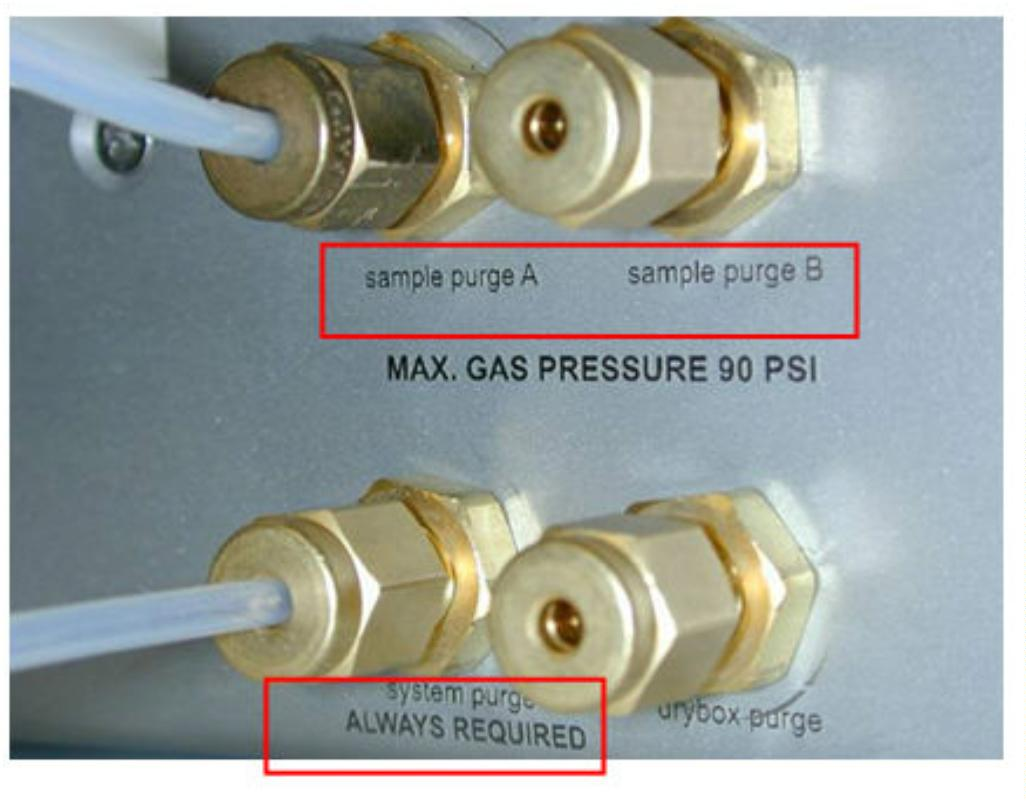

The DSC 4000 should always be used with a system purge gas inlet and two sample purge gas inlets at the back of the analyzer. A dry gas, such as nitrogen, should be used to purge the outer portion of the sample holder/heat exchanger assembly to prevent water vapor condensation on the measuring cell. The flow rate of the system purge gas is regulated by a needle valve preset to 40 ml/min.

Sample inlets A and B are part of the internal gas selector, which has two inlets and a single outlet, and are used for purging the furnace. It is recommended to use argon or nitrogen of 99.9% minimum purity for the task; however, other gases such as air or oxygen may be utilized as well. The flow rate of the sample purge gas is regulated by the software.

If you are using the DSC 4000 analyzer with an autosampler and dry box purge, it is necessary to employ either an H restrictor (P/N 01541498) or Float Displacement Flow Meter (P/N 02901624) to achieve the proper flow rate. A gas flow rate of 20 to 40 ml/min is suggested, and the gas must be dry.

To connect the sample and system purge gas lines to the DSC 4000 analyzer, begin by attaching 1/8-in. Teflon tubing to the analyzer using a female connector. Then, regardless of the other components in the purge gas line, connect the sample purge gas and system purge gas lines to the Teflon tubing. Ensure that the connections are securely tightened and sealed.

The back of the analyzer has the DSC 4000 system purge gas (1 pc) and two sample purge gas connectors mounted to it.

1 Attach the 1/8-in. Teflon tubing from the dry purge gas line to the inlet labelled "System Purge Gas ALWAYS REQUIRED".

2 Attach the 1/8-in. Teflon tubing from the system purge gas line to the inlet sample purge A.

Connect sample purge B (1/8-in. Teflon tubing) to a second sample purge line if desired.

The sample size will be dependent on what you are researching. Generally, 5 mg is the standard for normal nonisothermal runs. If you are looking to use high heating rates, it is recommended to reduce the mass to between 1.5 and 3 mg to avoid thermal gradients. Using lower heating rates with larger sample masses can yield a more precise heat evolution signal. However, when dealing with larger samples, it is essential to keep thermal gradients in mind. If you are using the DSC to anneal small samples at precise temperatures, there is no minimum sample mass required. However, you should still enter in a finite mass estimate, as you will not be able to accurately measure the heat evolution signal without knowing the exact mass.Finally, samples should be as flat as possible.

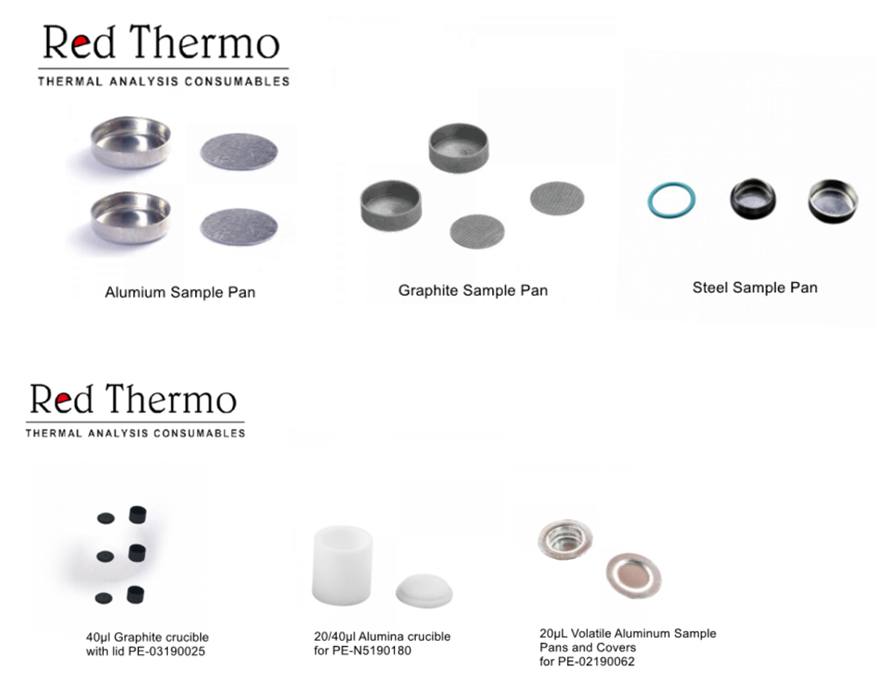

We offer DSC consumables in various materials, including aluminum, copper, steel, alumina and graphite. Depending on your sample's reactivity, the temperature range you need to work with and any pressure requirements, you can choose the most suitable pan. The standard pan/cover assembly is constructed using pure aluminum, and is crimped down when using copper or aluminum.(Please consult for more details: info@redthermo.com; or, whatsapp:+86 15377338375)