Your cart is empty.

shop now

Your cart is empty.

shop now

Below, the materials and techniques used to gather data from an STA 8000 are discussed. This instrument is capable of measuring the temperature and weight variations (relative to a base point) of a sample as a function of temperature and/or time.

CAUTION |

|

The instrument is capable of analyzing samples in powder, crystal, or granular form. Although the weight loss accuracy is largely unaffected by shape, the qualitative look of the run may differ depending on the sample configuration. The most effective performance is achieved with powder or fine granules. Bulk solids should be cut into small pieces with a razor or knife. For precise measurements, like calibrating the instrument using metal standards, heating and cooling the sample in the pan before running the test increases thermal contact and provides more consistent results. A sample weight of 10-20 mg is usually recommended for most experiments, though the balance can weigh up to 1500 mg, including the weight of the ceramic pans (around 200 mg).

To make sure the data is as accurate as possible, cover the sample in a layer of aluminum oxide (P/N 04190197) in the sample pan and the same amount in the reference pan. This will make the reflectivity of both pans equal, which will reduce any heat flow variation caused by the emissivity of the sample's surface.

The N520-2032 ceramic lids can be put on both the sample and reference pans to balance out their reflectivities without using aluminum oxide powder. This is also an easier method of finding out the sample weight, given that you can measure the weight of the pan and lid before adding the sample.

The STA 8000's sensor platform is optimized for the self-centering, thin-walled, ceramic sample pan that is included with the instrument. This type of sample pan centers itself in the pan and the pan centers itself on the platform, thereby improving the sample weight data collected. Additionally, users have access to three extra sample pans, which are available in the instrument's spares kit.

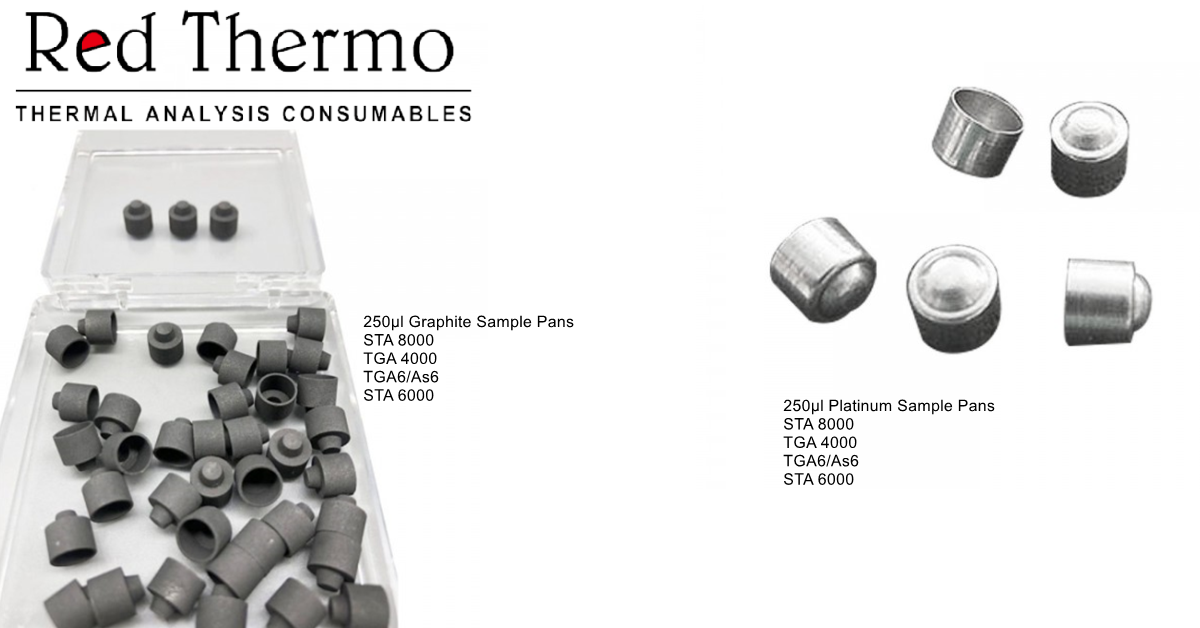

In addition, other sample pans, such as a graphite sample pan or a platinum sample pan, can also be employed. The only requirements that the pans must meet are that they do not react or melt within the temperature range of interest, and that the sample does not form alloys with the material of the sample pan.

The STA 8000 is equipped to function in multiple gas environments. At the rear of the analyzer, there is an inlet for one system purging gas, as well as two inlets for sample purging gas.

The system purge gas should be dry and inert and should flow through the microbalance chamber and into the sample chamber. This helps maintain a consistent environment in the balance, inhibits the absorption or release of vapors, and shields the balance from any gaseous products that may arise from the samples. The system purge gas flow rate is set at 45 ml/min. For the best performance of the analyzer, we strongly advise that the system purge gas is always available.

A purge gas flow rate of 20-40 ml/min, an inlet pressure of 2-3 bar (30-45 psi) and a maximum pressure of 6.2 bar (90 psi) can be used to regulate the environment in which the sample is tested. Air, nitrogen, argon, oxygen and helium are the recommended purge gases. When altering the purge gas or changing the flow rate, it is suggested to verify the temperature calibration. This is done via the Pyris software.

The purge gas is directed into the furnace/sample area proximate to the sample, reducing the dead volume and leading to a small gas change time constant, which is contingent on the flow rate.

For the best results, the gas atmosphere should be as pure as possible (at least 99.9%). An inert purge should be used if the analysis requires it, and there must be no oxygen present, as this could cause undesired reactions. Additionally, the gas must be dry; using a size 1A cylinder with a suitable regulator is recommended.

The sample's degradation byproducts exit the instrument through a tiny hole in the furnace cover. These byproducts may be hazardous, thus one should take the proper safety precautions, such as putting the instrument in a fume hood. Less volatile items condense on the colder spots of the analyzer like the bottom of the cover and the upper inner area of the cooling jacket. These areas can be effortlessly cleaned with the right solvent. Condensation can also form on the top inner side of the cooling jacket.