Your cart is empty.

shop now

Your cart is empty.

shop now

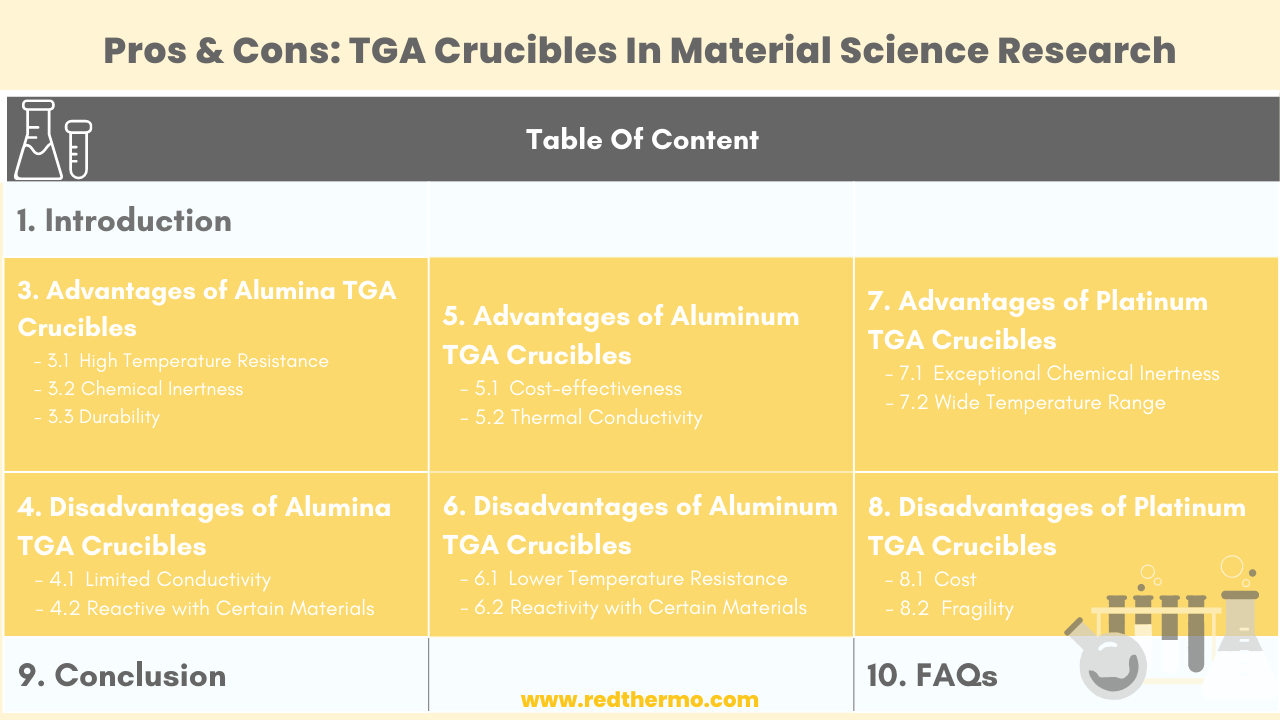

In material science research, Thermal Gravimetric Analysis (TGA) is a valuable technique for studying the properties of various materials. TGA crucibles, which provide a controlled environment for heating and weighing the sample, play a crucial role in this analysis. While TGA crucibles can be made from different materials, such as alumina, aluminum, and platinum, it is important to consider the advantages and disadvantages specific to each material. In this article, we will explore the advantages and disadvantages of using TGA crucibles that are made from alumina, aluminum, and platinum in material science research.

Alumina crucibles are known for their durability and mechanical strength. They can withstand thermal shock and mechanical stress, making them ideal for long-term use in TGA experiments. The robust nature of alumina crucibles allows for repeated use, reducing the need for frequent replacements.

Alumina crucibles have lower thermal conductivity compared to other materials such as platinum. This can result in slower heat transfer and longer equilibration times during heating processes. Researchers should consider this factor when designing experiments that require precise temperature control and quick ramp rates.

Although alumina is chemically inert to many substances, it can react with certain materials under specific conditions. For example, in the presence of alkalis or strong acids, alumina crucibles may undergo reactions that can compromise the accuracy of the analysis. Careful selection of materials and experimental conditions is necessary to avoid such interactions.

Aluminum TGA crucibles offer a cost-effective option for researchers. They are generally less expensive compared to materials like platinum, making them suitable for studies with budget constraints. This affordability allows for larger sample sizes or increased experimental replicates within limited resources.

Aluminum crucibles have high thermal conductivity, enabling efficient heat transfer during TGA experiments. This characteristic facilitates rapid temperature equilibration and precise control over heating rates, which can be beneficial for time-sensitive experiments or when analyzing materials with fast thermal responses.

Aluminum crucibles have limited temperature resistance compared to other materials like platinum. They are typically suitable for applications with temperature ranges up to 600-700°C. For experiments requiring higher temperatures, aluminum crucibles may deform or undergo structural changes, rendering them unsuitable.

Aluminum crucibles can react with certain substances, especially those containing acids or alkalis, leading to contamination and inaccurate results. It is essential to evaluate the compatibility of the sample with aluminum crucibles to prevent unwanted reactions that could affect the integrity of the analysis.

Platinum crucibles exhibit exceptional chemical inertness, making them highly suitable for a wide range of materials and experiments. They do not react with most substances, ensuring accurate and reliable results even when dealing with reactive or corrosive samples.

Platinum crucibles can withstand extremely high temperatures, often exceeding 1000°C. This high-temperature resistance allows researchers to analyze materials that require elevated thermal conditions without compromising the crucible's integrity.

Platinum crucibles are the most expensive option among the three materials discussed. Their high cost can significantly impact research budgets, making them less accessible for experiments with limited financial resources. Researchers need to carefully consider the trade-off between the benefits of platinum crucibles and their associated expenses.

Platinum crucibles are relatively fragile compared to alumina and aluminum. They require careful handling to prevent damage or breakage, which could lead to experimental failures or contamination. Researchers should exercise caution and employ proper handling techniques to ensure the longevity and reliability of platinum crucibles.

TGA crucibles play a vital role in material science research, enabling precise thermal analysis of various materials. The advantages of TGA crucibles include their high-temperature resistance, chemical inertness, versatility, accurate weight measurements, and compatibility with different sample types. However, limitations such as limited sample size, cost, fragility, and reusability challenges should also be considered. By understanding these advantages and disadvantages, researchers can make informed decisions when selecting and utilizing TGA crucibles in their material science research projects.

Q1: Can TGA crucibles be used for analyzing volatile samples?

Yes, TGA crucibles can be used for analyzing volatile samples. Open crucible designs are available that allow the evaporation of volatile substances during the heating process.

Q2: Are TGA crucibles suitable for studying air-sensitive materials?

Yes, TGA crucibles can be used for studying air-sensitive materials. Hermetically sealed crucibles are designed to prevent the sample from being exposed to the surrounding atmosphere, enabling the analysis of such materials.

Q3: Can TGA crucibles be reused?

In many cases, TGA crucibles can be reused. However, thorough cleaning is necessary to remove any residues or contaminants from previous experiments.

Q4: What are the common materials used for TGA crucibles?

Common materials used for TGA crucibles include alumina, platinum, and aluminum. The choice of material depends on factors such as temperature range, sample compatibility, and cost.

Q5: Can TGA crucibles withstand extreme temperatures?

Yes, TGA crucibles are designed to withstand high temperatures, allowing researchers to subject materials to extreme thermal conditions without compromising the crucible's integrity.