Your cart is empty.

shop now

Your cart is empty.

shop now

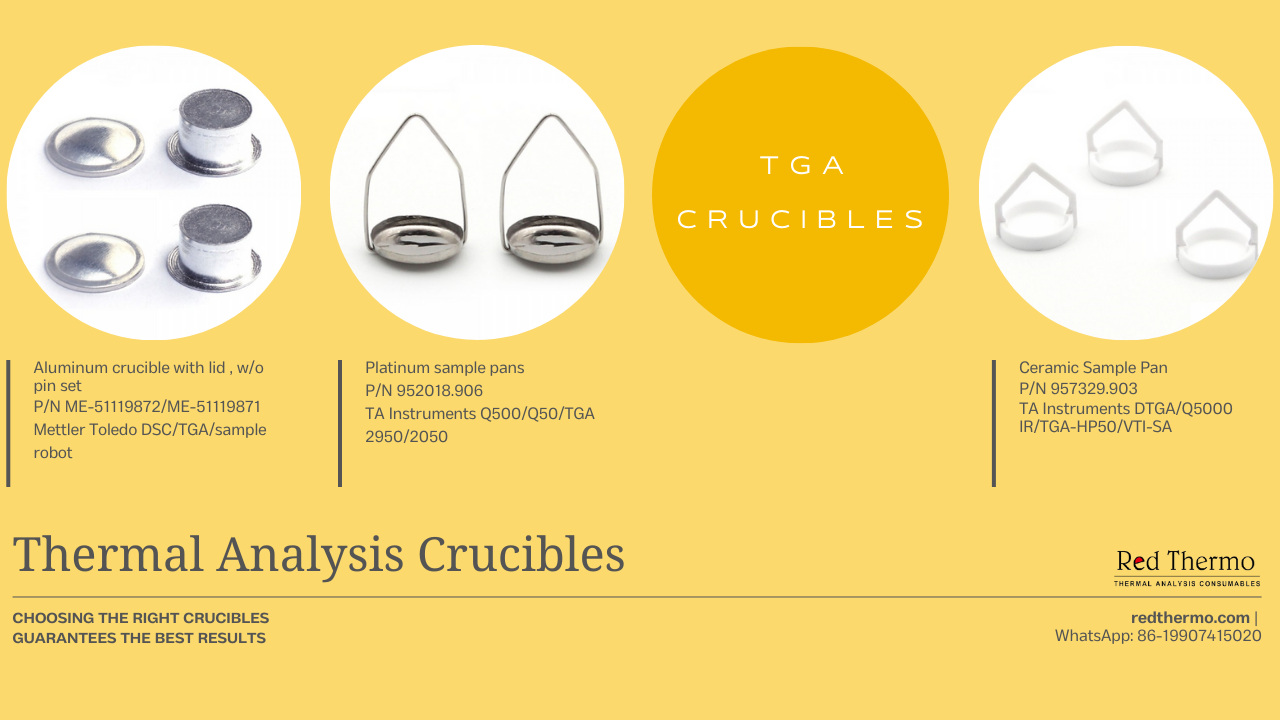

The choice of crucible material can significantly impact the results of your TGA analysis. Different materials have varying thermal properties and reactivity, which can lead to erroneous weight loss or gain readings. It's vital to select a crucible material that is compatible with your sample and the desired temperature range of your analysis. Common crucible materials include aluminum, platinum, and ceramic materials, each with their own advantages and limitations.

Improper handling and preparation of crucibles can introduce contaminants or inconsistencies in your analysis. Crucibles should be thoroughly cleaned and dried before use to prevent any residual moisture or impurities from affecting the sample's behavior. Mishandling crucibles during loading or transferring samples can also lead to inaccuracies in weight measurements.

Accurate sample loading is crucial for reliable TGA results. Overloading a crucible can lead to spillage during heating, causing an imbalance in weight measurements. Underloading, on the other hand, might not provide a representative sample for analysis. Following recommended guidelines for sample mass based on crucible size is essential.

Before conducting TGA analysis, it's essential to calibrate the instrument and establish a baseline measurement. Neglecting this step can result in misinterpretation of weight changes. The baseline measurement accounts for any weight loss or gain that occurs due to factors other than the sample itself, such as crucible reactions or equipment drift.

Abrupt temperature changes can cause thermal shock to the crucible, leading to cracking or premature wear. Gradual temperature ramps are preferred to ensure the crucible's structural integrity and accurate weight measurements. Sudden temperature fluctuations can also affect the sample's behavior and introduce errors.

Maintaining a consistent gas flow rate is essential for controlling the sample environment and preventing unwanted reactions. Deviations in gas flow can impact the rate of weight change observed during the analysis. It's crucial to follow the manufacturer's recommendations for gas flow rates and regularly check for any fluctuations.

The position of the thermocouple is vital for accurate temperature measurements. Placing the thermocouple too close to the sample or the crucible walls can lead to inaccurate temperature readings. Ensuring the thermocouple is appropriately positioned within the crucible chamber enhances the reliability of the obtained data.

Sample purity directly influences the results of TGA analysis. Impurities in the sample can lead to unexpected weight changes that are unrelated to the sample's intrinsic properties. Thoroughly purifying and characterizing the sample before analysis is essential for obtaining meaningful results.

New crucibles or those that haven't been used for a while should be conditioned before analysis. This involves subjecting the crucible to a series of controlled heating and cooling cycles to stabilize its behavior. Skipping this step can lead to erratic weight changes and inaccurate measurements.

Calibrating the temperature readings of the TGA instrument is crucial for result accuracy. Temperature inaccuracies can lead to incorrect determination of weight loss or gain rates. Regular temperature calibration using standard reference materials helps maintain the instrument's precision.

In the realm of Thermogravimetric Analysis, the quality of results hinges on meticulous crucible usage. By avoiding common errors like selecting the wrong crucible material, mishandling crucibles, and neglecting proper calibration, researchers and industry professionals can ensure accurate and reliable TGA outcomes. The careful selection of crucible material, coupled with precise sample loading and consistent instrument maintenance, sets the stage for meaningful analyses that drive scientific understanding and innovation.