Your cart is empty.

shop now

Your cart is empty.

shop now

Importance of Crucible Selection

A suitable crucible is vital for obtaining accurate and precise results in high-temperature DSC measurements. The properties and characteristics of the crucible significantly impact the thermal behavior of the sample material. Therefore, it is essential to consider various factors before making a selection.

The Key Factors of Crucible Selection

There are several key factors to consider when selecting a thermal analysis crucible for accurate and reliable DSC measurements.

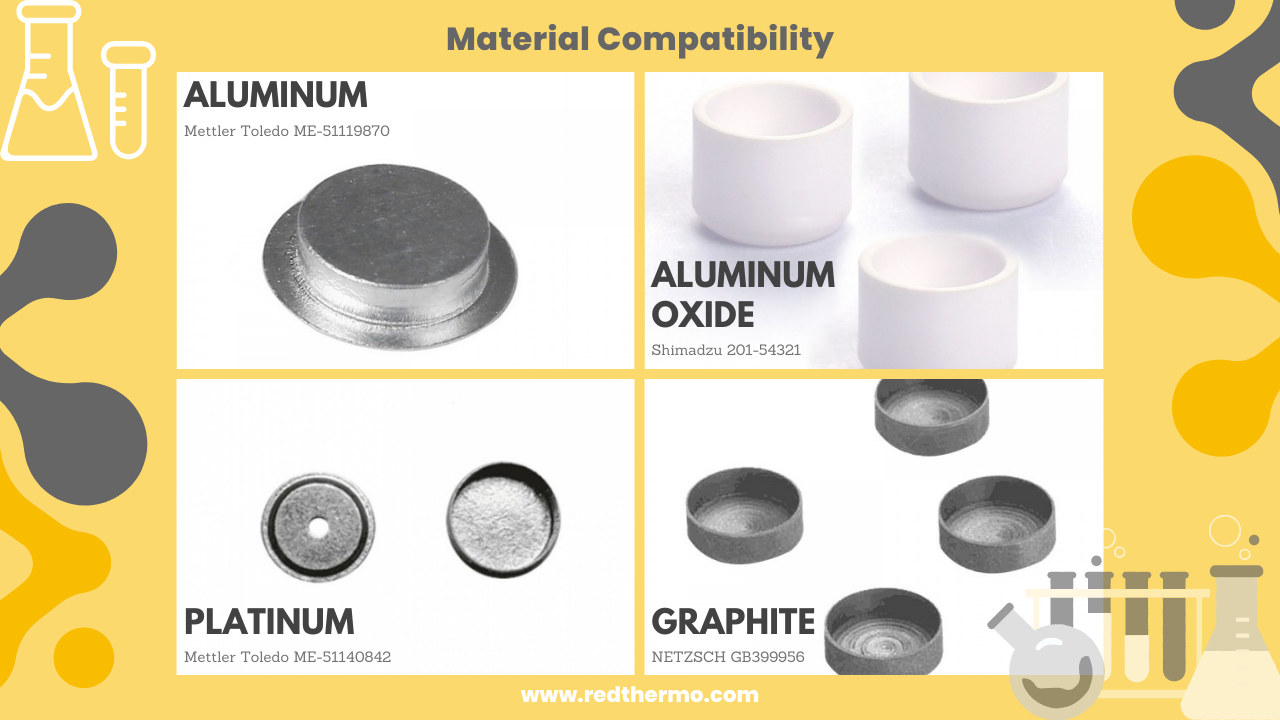

The choice of crucible material is crucial as it determines the compatibility with the sample material and the temperature range of the experiment. Common crucible materials include aluminum, aluminum oxide, platinum, and graphite. Each material has its advantages and limitations, such as chemical resistance, reactivity, and thermal conductivity. Select a crucible material that is chemically inert, thermally stable, and compatible with your sample.

The temperature range of your DSC measurements should align with the capabilities of the selected crucible. Different materials have different melting points and maximum operating temperatures. Ensure the crucible can withstand the desired temperature range without deforming, reacting, or releasing impurities affecting measurement accuracy.

The thermal conductivity of the crucible material affects the heat transfer between the sample and the DSC instrument. High thermal conductivity allows for efficient heat transfer, ensuring accurate temperature measurements. However, materials with low thermal conductivity can be advantageous when analyzing samples with low thermal diffusivity. Consider the thermal properties of the sample and the desired measurement sensitivity when choosing the crucible material.

The crucible's sample capacity should be appropriate for the material available for analysis. Consider the volume or mass of the sample material to ensure it fits within the crucible without overflowing or compromising the measurement accuracy. Overloading the crucible can lead to inaccurate results and potential safety hazards.

The design of the crucible plays a crucial role in maintaining sample integrity, ensuring proper heat transfer, and facilitating easy handling. Consider the following design aspects when selecting a crucible:

The shape and size of the crucible should be compatible with the DSC instrument and the experimental setup. Common crucible shapes include cylindrical, conical, and flat-bottomed. Choose a shape that allows for uniform heat distribution and efficient sample handling.

Some crucibles have lids or covers to prevent sample evaporation, contamination, and heat loss. The lid configuration should provide a tight seal without interfering with the measurement process. Consider whether a lid is necessary for your experiment, and choose a crucible with the appropriate lid configuration.

The crucible's thermal properties, such as heat capacity and thermal diffusivity, affect the heating and cooling rates during DSC measurements. Rapid heating and cooling rates may require a crucible material with high thermal conductivity to ensure accurate temperature control. Consider the heating and cooling requirements of your experiment and choose a crucible that can meet those requirements.

The durability of the crucible is essential, especially if you plan to reuse it multiple times. It should withstand repeated heating and cooling cycles without significant degradation. Consider the long-term durability of the crucible material to ensure its longevity and cost-effectiveness.

Contamination from previous experiments can affect the accuracy of DSC measurements. Choose a crucible material that minimizes the risk of contamination and allows for easy cleaning and reusability. Some materials may require specialized cleaning procedures or disposable crucibles for certain applications.

The cost of the crucible is an important factor to consider, especially when working on a budget. Different crucible materials come at varying price points. Evaluate the balance between cost and performance to select a crucible that meets your experimental requirements without exceeding your budget.

Before using a new crucible, it is essential to prepare it appropriately to remove any residual impurities or contaminants. Follow the manufacturer's guidelines for cleaning and preheating the crucible to ensure optimal performance and accurate measurements.

Regular cleaning and maintenance of the crucible are necessary to prevent contamination and maintain its performance. Follow the recommended cleaning procedures and handle the crucible with care to avoid damage or premature wear.

Consider reputable crucible manufacturers known for their quality and reliability. Research different manufacturers, read customer reviews, and consult with experts in the field to identify reliable sources for your crucible needs.

Reading user reviews and recommendations can provide valuable insights into the performance and suitability of different crucibles. Learn from the experiences of other researchers and professionals who have used specific crucibles for high-temperature DSC measurements.

Ensure you follow proper safety precautions when handling high-temperature crucibles and conducting DSC measurements. Use appropriate personal protective equipment (PPE), be aware of potential hazards, and operate within the recommended temperature and pressure ranges.

Selecting a suitable crucible is critical in performing accurate and reliable high-temperature DSC measurements. Consider the material compatibility, temperature range, thermal conductivity, design considerations, sample capacity, and other factors discussed in this article. By making an informed decision based on these critical factors, you can optimize your thermal analysis experiments and obtain meaningful results.

A crucible in thermal analysis is a container or vessel used to hold the sample material during high-temperature DSC measurements. It is designed to withstand elevated temperatures and provide a controlled environment for accurate thermal analysis.

The choice of crucible material is crucial because it determines the compatibility with the sample material and the temperature range of the experiment. Different materials have varying properties, such as chemical resistance, reactivity, and thermal conductivity, which can significantly impact the accuracy and reliability of DSC measurements.

To determine the appropriate crucible size for your sample, consider the volume or mass of the sample material. It should fit within the crucible without overflowing or compromising the measurement accuracy. Overloading the crucible can lead to inaccurate results and potential safety hazards.

Yes, crucibles can be reused depending on the material and application. Some crucibles are designed for single-use and disposable, while others can be cleaned and reused multiple times. It is essential to follow the manufacturer's guidelines for cleaning and maintenance to ensure the crucible's longevity and performance.

Yes, there are safety precautions to consider when using high-temperature crucibles. Always use appropriate personal protective equipment (PPE) such as heat-resistant gloves, goggles, and lab coats. Be aware of potential hazards associated with high temperatures and handle the crucibles with care to avoid burns or accidents.