Your cart is empty.

shop now

Your cart is empty.

shop now

Thermal analysis crucibles are small containers that hold samples during various thermal analysis techniques, including Differential Scanning Calorimetry (DSC). These crucibles are made from materials with high thermal stability to withstand the extreme temperature conditions experienced during the experiments. The choice of crucible material depends on the specific application and the desired thermal and chemical properties.

In DSC measurements, thermal analysis crucibles are essential for accurate and reliable results. They provide a controlled environment for the sample, isolating it from the surroundings and preventing any external influences. The crucibles also play a vital role in the heat transfer process, allowing for precise temperature control and measurement. Without suitable crucibles, it would be challenging to perform DSC measurements effectively.

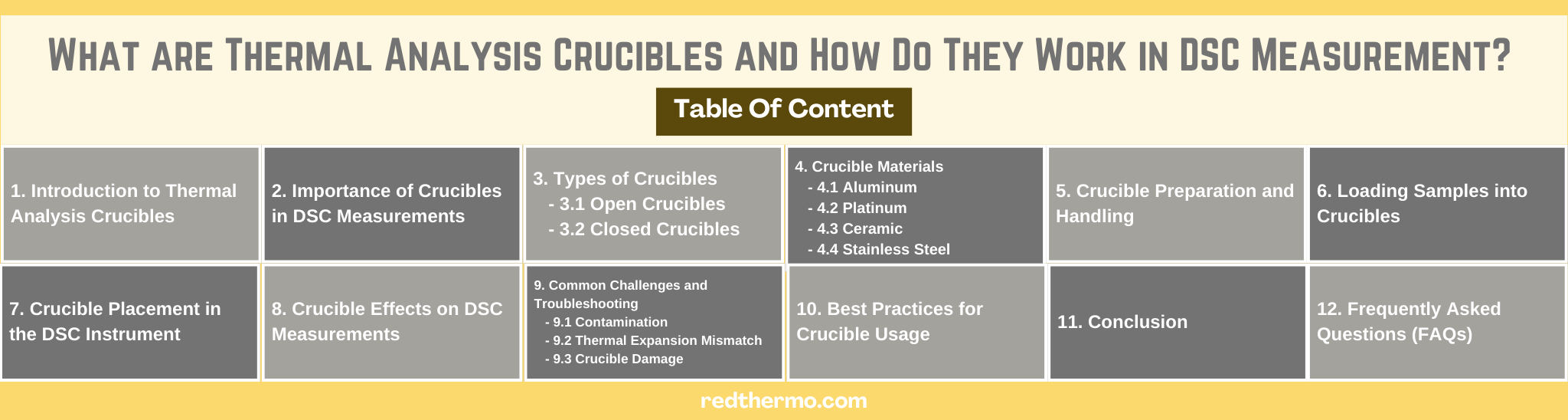

Two main types of thermal analysis crucibles are used in DSC measurements: open and closed.

As the name suggests, open crucibles have an open design, allowing for better sample exposure to the surrounding atmosphere. These crucibles are commonly used for samples that require good airflow and efficient gas exchange during the experiment. Open crucibles are typically made from materials such as aluminum or platinum.

On the other hand, closed crucibles have a sealed design that prevents direct contact between the sample and the surrounding atmosphere. These crucibles are ideal for samples sensitive to atmospheric conditions or requiring a controlled environment. Closed crucibles are often made from materials like aluminum or stainless steel.

The choice of crucible material depends on factors such as the desired temperature range, chemical compatibility, and reactivity with the sample. Here are some common materials used for thermal analysis crucibles:

Aluminum crucibles exhibit high thermal conductivity, allowing for efficient heat transfer during DSC measurements. This property ensures accurate temperature control and precise heat flow measurement within the sample.

Aluminum is a lightweight material, which is advantageous for handling and manipulating crucibles during sample preparation and loading. The low mass of aluminum crucibles also minimizes the influence of the crucible itself on the heat flow within the sample, allowing for more accurate DSC measurements.

Aluminum is relatively easy to machine, enabling the manufacturing of intricate shapes and designs for crucibles and lids. This versatility in shaping the crucibles facilitates sample placement and enhances the contact between the sample and the crucible, improving the accuracy of the measurements.

An aluminum crucible is generally compatible with various sample types encountered in DSC measurements. It does not react with common materials or introduce significant interference or contamination to the samples, ensuring accurate and reliable results.

Platinum crucibles are highly inert and resistant to corrosion, making them ideal for demanding applications. They are commonly used when analyzing samples with reactive components or at extremely high temperatures.

Ceramic materials exhibit excellent thermal stability and withstand high temperatures without significant deformation or degradation. DSC measurements involve subjecting samples to varying temperatures, and ceramic crucibles and lids can withstand the temperature range typically encountered in DSC experiments.

Ceramics are chemically inert and do not react with most substances commonly used in DSC measurements. This property ensures that the crucibles and lids do not introduce interference or contamination to the analyzed samples, thereby allowing accurate and reliable results.

Ceramic crucibles have relatively low thermal conductivity, which is beneficial for DSC measurements. They act as insulators, minimizing heat loss from the sample and enabling precise measurement of heat flow during the experiment. This characteristic helps to maintain the integrity of the temperature profile and improve the accuracy of the DSC measurements.

Despite being brittle, ceramic materials used in DSC crucibles and lids can exhibit high mechanical strength when properly designed and manufactured. During DSC experiments, they can withstand the mechanical stresses associated with sample handling, loading, and thermal cycling.

They are chemically inert and do not react with different sample matrices, ensuring that the material of the ceramic crucible and lid does not influence the behavior or properties of the samples under analysis.

Stainless steel crucibles exhibit exceptional resistance to corrosion, making them suitable for applications involving high-pressure and chemically reactive environments. DSC measurements often involve aggressive chemicals or elevated temperatures, and stainless steel can withstand these conditions without corroding or degrading.

They possess excellent mechanical properties, such as high tensile strength and durability. The stainless steel crucibles and lids used in DSC experiments must withstand high pressures, ensuring that the sample remains within the vessel during the measurement process. Stainless steel's robustness ensures the crucibles and lids can withstand the pressure without deformation or failure.

DSC measurements involve subjecting samples to varying temperatures, and the stainless steel crucible exhibits good thermal stability. It can withstand high temperatures without significant expansion or distortion, which is crucial for accurate and reliable measurements. This property permits precise control and measurement of heat flows during DSC experiments.

Stainless steel is compatible with various sample types and chemicals commonly used in DSC experiments. It does not react with most substances, ensuring that the material of the crucible and lid does not interfere with the sample being analyzed. This compatibility is crucial to obtain accurate and representative DSC measurements.

Proper preparation and handling of crucibles are crucial to ensure accurate and repeatable DSC measurements. Before use, the crucibles should be cleaned thoroughly to remove contaminants that may affect the analysis. Care should be taken to handle the crucibles with clean gloves or tongs to prevent contamination from oils or other substances present on the skin.

The process of loading samples into crucibles requires attention to detail. It is important to measure the appropriate amount of sample to ensure consistent results. The sample should be evenly distributed within the crucible to facilitate uniform heating and reliable measurements.

The placement of the crucible within the DSC instrument is crucial for accurate temperature measurement. The crucible should be positioned to ensure good thermal contact with the temperature sensor, allowing for precise detection of heat changes during the experiment.

The choice of crucible material and design can impact the DSC measurements. Different crucibles may exhibit varying thermal properties, affecting the recorded heat flow and temperature profiles. Understanding these effects is important for data interpretation and comparison between experiments.

During DSC measurements, several challenges related to crucibles may arise. Here are some common issues and troubleshooting tips:

Contamination of crucibles can occur due to residual sample residues, improper cleaning, or cross-contamination between experiments. To mitigate this, it is essential to clean the crucibles thoroughly after each use and avoid using the same crucible for different samples without proper cleaning.

Thermal expansion mismatch between the crucible and the sample can lead to mechanical stress and potential damage. To prevent this, it is crucial to select a crucible material with a compatible coefficient of thermal expansion (CTE) with the sample material.

Crucibles may wear and tear over time, especially when subjected to frequent heating and cooling cycles. Regular inspection and replacement of damaged crucibles are necessary to ensure accurate and reliable DSC measurements.

To maximize the effectiveness of thermal analysis crucibles in DSC measurements, the following best practices should be considered:

- Select the appropriate crucible material based on the sample's properties and experimental requirements.

- Thoroughly clean the crucibles before each use to prevent contamination.

- Ensure proper loading and distribution of samples within the crucibles.

- Handle the crucibles with care to avoid damage or contamination.

- Regularly inspect crucibles for signs of wear and replace them when necessary.

Thermal analysis crucibles are vital components in DSC measurements, providing a controlled environment for samples and enabling accurate temperature measurements. Researchers can obtain reliable and reproducible results in their thermal analysis experiments by selecting the right crucible material and following best practices for their usage.

Not all crucibles are suitable for high-temperature applications. Materials like aluminum and platinum are commonly used for their high-temperature resistance, while others like ceramic and quartz have specific temperature limits.

It is generally recommended to clean crucibles thoroughly before reusing them for different samples to avoid contamination and cross-contamination. However, some crucibles may be designed for single-use only.

Yes, the choice of crucible material can influence the recorded heat flow and temperature profiles in DSC measurements. Different crucibles have varying thermal properties that can impact the results.

Crucibles should be regularly inspected for signs of wear or damage. The inspection frequency depends on the frequency of usage and the specific application. It is good practice to inspect crucibles before each use visually.